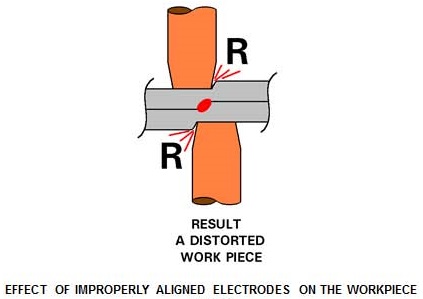

Proper alignment of the resistance welding electrodes is very important to insure proper force application and current flow through the electrode face. If not set up properly the part can be distorted and/or the electrode face can have exceedingly high current densities. This can result in distorted parts, expulsion and excessive electrode face wear.

Most electrode alignment is done by eyeball. Bringing the electrode together with the current off and hold in place at modest force. Then with a straight edge see how they look. Make adjustments. Try again till it is what you desire. A laser light could also be used to align the holders/electrodes.

As a final check close the electrodes on a piece of old fashioned carbon paper doubled over with a piece of paper or card stock in between. Look at the carbon paper mark on the card stock/paper and see if there is a full mating circle.

Additional related articles in this blog are:

“IS ELECTRODE ALIGNMENT IMPORTANT?”

“HOW DOES ELECTRODE ALIGNMENT AFFECT PROJECTION WELDING?”

Reference: RWMA – “Resistance Welding Manual 4th Edition”