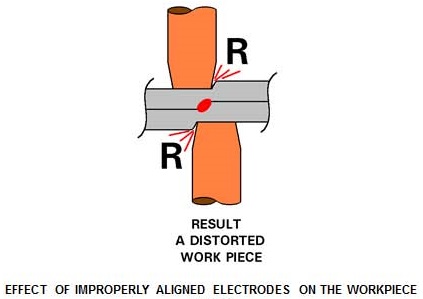

Spot welding electrodes have a large influence on the resistance welding process. Their alloy and face size contribute to the development of the proper weld nugget. All of this assumes that the electrodes have been installed properly. This means proper water cooling and water tube location and good alignment. Alignment means that the face of the electrode is square and parallel to the part being welded. In addition the upper and lower electrodes faces should line up vertically with each other. The goal is to apply all forces on the same central axis. This prevents the electrodes from imparting and twist or distortion into the part during the welding operation.

Electrodes aligned improperly sometimes skid on the workpiece during welding.