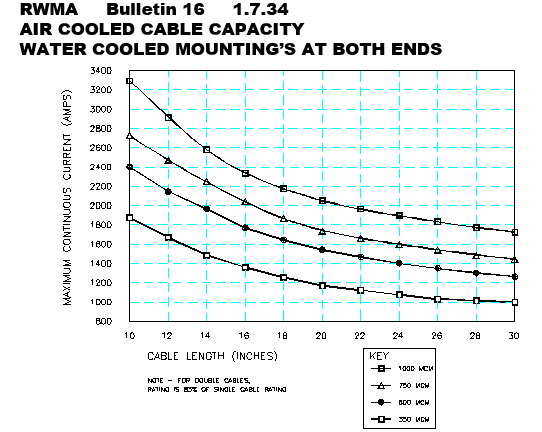

Resistance welding cables are made in different conductor sizes and lengths. Additionally they are manufactured as air cooled or water cooled. The air-cooled version must be attached to water cooled surfaces at both ends. The are generally covered with a protective sheath to prevent abrasion. Select the cable based on the ampacity and length required.

It is important to select the proper size for the job and minimize connection joints and length to reduce resistance in the overall circuit. One must know the expected current that is going to be passed. This with the distance from the transformer to the electrode one has an approximate length.

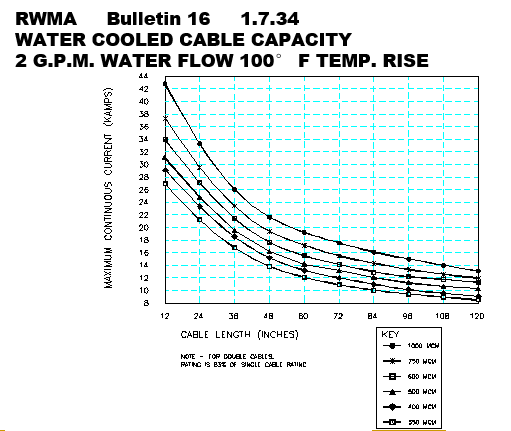

Using the desired current and length the proper MCM (Maximum Continuous Current) cable can be determined for the application.

Water cooled cables offer higher conduction capacities with a premium cable if required.

Reference: RWMA Bulletin 16