Projection welding is a very widely used process from cross wire welding of fencing, to nut welding, to water tight water heater fittings, to a handle on a kitchen measuring cup. They all perform different important functions but all depend upon the shape of the part to concentrat the heat and power for nugget formation. The machine and electrodes have to hold the part in place for this to occur or we have chaos.

Factors that are important are the machine functions of pressure current and time. AWS covers general maintenance of the machine and will not be addressed here, see the reference.

A few specific items deserve listing:

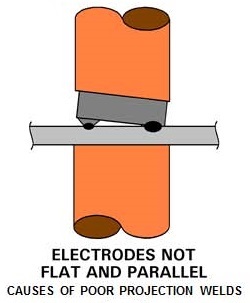

• ALIGNMENT Force must be delivered perpendicular to the weld face. If alignment is bad some projections will see the proper force and others likely will be expelled when the current is applied. ROCKER ARMS are not acceptable due to non-perpendicular force application

• FOLLOW-UP must be fast. This is the ability of the servo or cylinder to immediately react and maintain full force the millisecond that the projection starts to collapse. There cannot be cycles or seconds of hesitation or lag before the force reacts. The force must be maintained while the projection collapses.

• PROJECTION SIZE AND SHAPE – Historically projections are frequently not consistent in size and shape. This means that in multi projections each time a part is welded, conditions vary. Are two projections touching and not the third? Is one projection much larger than the other others? Heating will vary. Expulsion may be present. A projection may be blown away. Some variation can be accounted

for but there is a limit. Missing or severely under or oversized can lead to problems.

• ELECTRODES are not normally an issue. They merely deliver current and force into the part. They do not concentrate either. The part design does. In the case of nut welding insulating pins are often used. If they wear and cease to insulate that is an issue and must be accounted for.

Other articles in this blog related to this topic are:

How do you develop a projection welding process?

How do you develop a projection welding schedule?

Reference: AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

RWMA – RWMA Resistance Welding Manual 4th Edition