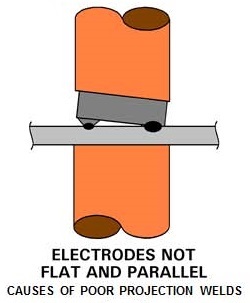

Poor electrode alignment or being out of parallel can be a serious problem with projection welding. Generally projection welding involves making several small projections welds with one electrode delivering the force and current to the part. Therefor if the electrode contacts one side of the part first those projections will be in the most intimate contact and carry most of the current. Projections on the other side of the part will have little if any force and could be subject to expulsion when the current initiates. This is both dangerous and bad for weld quality since the projection may be expelled when the current initiates.

Rocker arm machines are not good choices for projection welding because they by design apply force on an arc motion and can lead to misalignment and skidding of the projections.

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Manual Section 1, Chapter 3