Projection welding is performed with many style projections - rings, dimples and slots to name a few. The sizes and designs will depend upon the material being welded its thickness and the design and location for the projection. Some projection welding does not require a design as in cross wire welding. Merely place the two wires in contact at 90 deg and they are ready to weld. Two flat pieces of low carbon steel however require a projection of some sort. The thickness of the material also plays a part in the height and diameter of the projection. Material composition factors into the design.

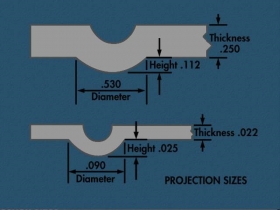

Typical projections for low carbon steel

Other references with more size combinations and materials can be found in the AWS Standard C1.1 Recommended Practices for Resistance Welding and the RWMA Manual Section 1, Chapter 3.

Reference: AWS C1.1 Recomended Practices for Resistance Welding

RWMA: Resistance Welding Manual 4th Edition