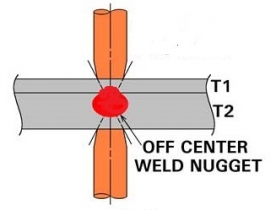

“X” theory can be referred to as heat balancing in spot welding where a 90 degree X drawn through the weld nugget at the faying surface and intersecting the surface can indicate the proper electrode face to move the nugget to the faying surface. In the drawing below the upper electrode would remain the same diameter and the lower would increase in diameter to move the nugget up if a 90 degree X were drawn.

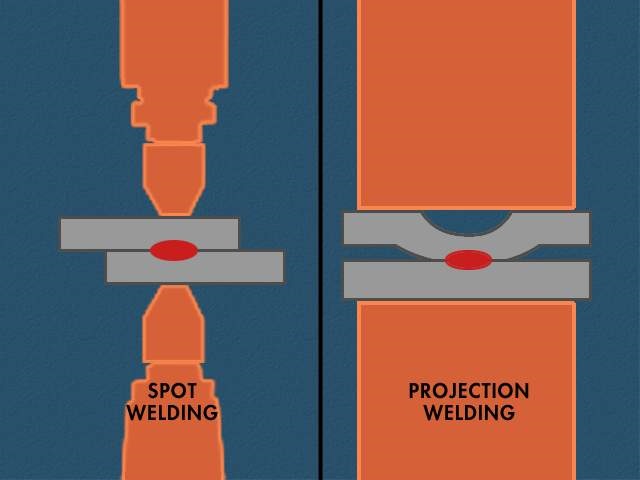

In projection welding heat balance and “X” theory are not necessary because the projection is designed to concentrate the heat where you need it, at the faying surface.

The electrode geometry and size is only necessary to deliver current and force to the part.

Normally flat electrodes with diameter larger than the work piece are used.

Alloy selection is generally Class 2 but if mechanical wear is an issue Class 3 may be used. In the case of nut welding where heat may be an issue Class 11 copper/tungsten frequently is an economical choice with a coated or ceramic locator pin.

The electrodes mainly capture and align all components for the welding operation. In the end they provide the force and current. Electrode size is generally not critical. Usually the electrode is larger than the nut, bolt or wire being welded.

In general projection welding is an easy job for the electrode since part design determines the weld nugget size, shape and concentrates the heat.

Reference:

RWMA Manual, Fourth Edition