Yes, projection welds like any spot weld if not performed properly have the potential to generate weld spatter or expulsion. The variables that must be controlled are alignment, projection size, shape or missing, force follow-up and weld schedule. Their variation may result in spatter if:

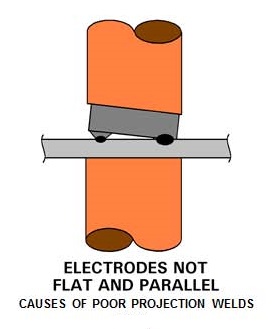

ALIGNMENT: If the pressure is not applied and the multiple projections do not make contact at the same time or with the same pressure, one or more will carry most of the current and overheat. This overheated projection or projections have the potential to expel material. The final projection when it makes contact will do so under current which means an arc will occur. An arc can always lead to expulsion.

PROJECTION SIZE OR SHAPE: When welding multiple projections, if the projections are not the same size, shape or missing there is a potential for inconsistent welding. When the projections make contact at the same time, but they are different sizes they can heat at different rates. One projection can overheat which could lead to expulsion. If size is dramatically different, one projection may not make initial contact. When the other projections begin to collapse due to carrying too much current the then the last projection will make contact with the current on and make an arc. Flash, expulsion or spatter could result from the arc or from the over heated original contacted projections.

FORCE FOLLOW-UP: It is imperative that as the projection begins to heat up and collapse that the weld head maintains force and full pressure on the projection as it collapses. This insures a good strong weld. If the weld head sticks or is slow the weld strength will suffer and the strength will be low or in an extreme case no weld and flash, expulsion or spatter could result.

WELD SCHEDULE: A proper weld schedule is always important to efficiently apply the proper force, bring the projections up to temperature and forge the weld with the proper fast follow up.

Projection welding parameters are readily available in published weld schedules referenced below. In general they have relatively short weld times and perform very well as documented. There are cases in which the circumstances in manufacturing are not ideal and variations from the standard are necessary. In these circumstances a change in the weld schedule may help.

Some but not all of the above issues may be corrected with weld schedule changes. Upslope or a slow rising current over a few cycles might give the part time to seat itself and put the badly aligned uneven projections in contact so they will weld rather than become expulsion. You can’t replace a missing projection but seat the projections present before hitting them with full power. Remember that fast-follow-up is always necessary. Be sure the equipment is capable of fast-follow-up.

FAST-FOLLOW-UP SPRING IN RAM FAST-FOLLOW-UP HOLDER

A related article on this subject in this blog is:

What are the Do's and Don'ts for projection welding?

References: Projection welding schedules are available in the Resistance Welding Manual published by RWMA/AWS

AWS Standard C1.1 Recommended Practices for Resistance Welding published by AWS.

Photos courtesy of T.J. Snow Co. and Tuffaloy Products Inc.