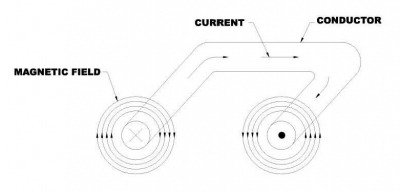

It is a law of physics that current flowing through a conductor will generate a flux field around it. This flux field is a magnetic field and is the basis of electric motors, generators, and transformers.

MAGNETIC FIELD AROUND ELECTRICAL CONDUCTOR

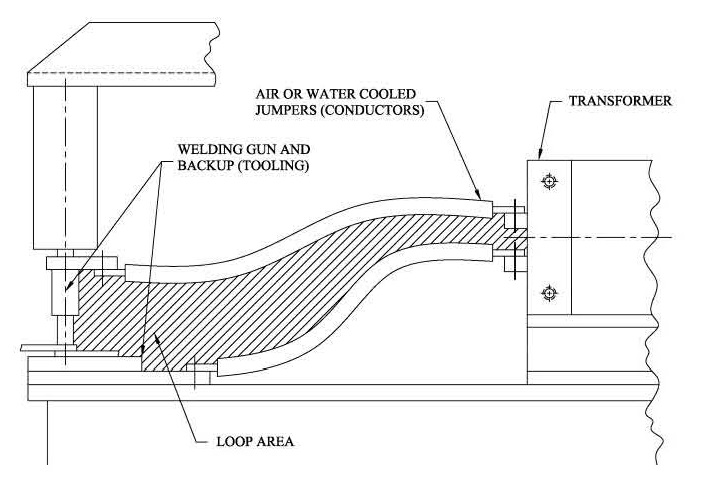

All resistance welding machines have this flux field in the throat or loop area.

THROAT OR LOOP AREA WITH MAGNTIC FIELD

Any magnetic material that enters this throat area will be affected by the magnetic field, if this is an AC machine. DC or MFDC machines still have magnetic affects but do not have the reactance of an AC machine and will not cause the part to heat up and drain the power from the weld.

Another issue is that as the welding machine initiates it could cause parts indexing into the throat of the machine to move if they are not held in the fixture properly. Tooling must hold parts tightly to prevent them from moving as the magnetic field builds and collapses while the parts are moving into the throat. The magnetic field is a given. It will not go away.

Over time weld flash builds up on the frame and tooling. If it is not removed it can build up heat and drain the power of the welder. Stray current paths can occur in the weld flash build up and unusual operations can be noted. This can be solved by preventive maintenance and weld flash removal.

References: RWMA Resistance Welding Manual 4th Edition

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines