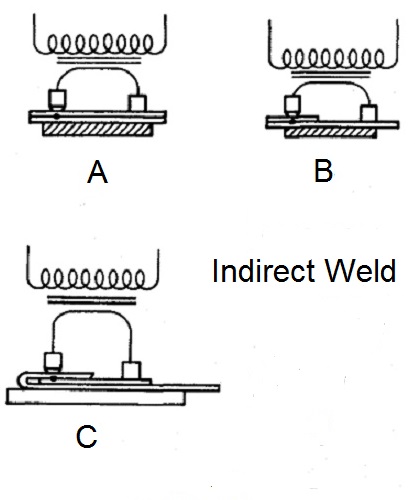

Indirect welds use similar machine and power set ups to series welds. The difference is that one pole off the transformer is connected to a pick up conductor rather than an electrode. Therefore the current returns to the transformer through this location but no weld is made. This process eliminates marking at the pickup point and the need for electrodes on the other side of the part when only when weld is required.

Note that in each sketch one electrode is contoured/pointed to concentrate the heat and weld. The other is flat to dissipate the heat and make no weld. There will be little marking of the part on the back side and none at the pickup point.

The clinched part in “C” can be welded with virtually a full cosmetic weld on the back side. Shunting currents are still present as in series welds in “A”. Current can travel in the upper sheet without passing through the weld to reach the return contact. If the distance to the pickup electrode is sufficient this can be reduced to a minimum. In example “B” there is no shunting current since the top work-piece does not touch the pickup electrode. All current had to pass through the weld to reach the return contact point.

Reference: RWMA: Resistance Welding Manual, Section 1, Chapter 2