A direct weld is a standard spot weld where the current path is directly through the workpiece between opposing electrodes. This is the easiest weld to produce. The electrodes size and face shape can be optimized for the application. The face can be radius or flat to produce the desired spot weld.

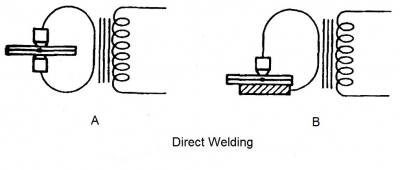

Figure A exhibits the simplest ideal weld set up with two equal opposing electrodes. If the workpiece materials are the same and equal thickness the resultant nugget should be centered.

In Figure B a large flat surface electrode or mandrel is shown. The upper is a movable electrode with a flat or radius face. The lower electrode is a fixed flat faced electrode as shown. This set up might be employed to reduce the heating or indentation on the lower workpiece. This could represent a surface where a cosmetic weld surface is specified (no weld indentation or heat effect).

Reference: RWMA, Resistance Welding Manual Section 1, Chapter 2