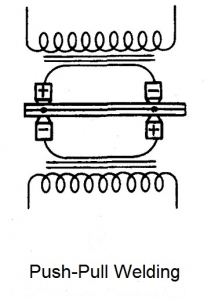

Another variation of the series weld is the push-pull weld. In this process the electrodes are connected to separate secondary circuits on both sides of the weldment. The polarities are arranged as shown for proper current flow. Shunting current is still present but now in both workpieces. The voltage between the electrodes increases the weld current to shunting current ratio when compared to other series weld set ups. Therefore you get more power delivered to the weld.

In this arrangement two welds are made. This is a push-pull series weld set up. If one substituted large flat electrodes at one position, no weld would occur and this would become a push-pull indirect weld. (See indirect weld) Push-pull welding requires electrode and power access to both sides of the part. There can be electrode and heat marking on both sides of the part.

Reference: RWMA: Resistance Welding Manual, Section 1, Chapter 2