All suspended gun systems consist of potentially four components that may require water cooling. They are the control, the transformer, the secondary cables and the electrodes with their copper holders. The traditional suspended gun systems would have all of these components. Newer systems may use transguns, which would eliminate the secondary kickless cables.

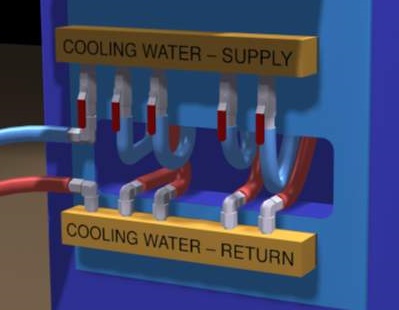

Depending upon your system, an input and output water manifold would be assembled similar to the one shown below. The output and input water lines would be routed to the components that require water cooling. The plant water supply would be connected to the supply side of the manifold. This could be city water, plant water tower system or a chiller. The return would connect to a sewer drain, water tower return or chiller return.

WATER MANIFOLD

If the control has a smaller SCR, it may be air cooled and not require water cooling. If this is a transgun there are no secondary cables. This leaves the transformer and electrode/holders as the components requiring cooling.

If it is two components or four always run water directly to the electrodes and holders. Never feed electrodes with water used previously to cool another component.

The manufacturer of the equipment should have specifications on the flow requirements and temperatures for the equipment. A good source for information is AWS J1.2 Guide to the Installation and Maintenance of Resistance Welding Machines.

For specific help local Manufacturer Rep’s and Distributors in your area are familiar with installing and setting up equipment and can help.

Reference: AWS J1.2M/J1.2:2016 Guide to the Installation and Maintenance of Resistance Welding Machines

RWMA- Resistance Welding Manual 4th Edition