In another article in this blog the proper amount of water for seam welding was addressed:

IS THE PROPER AMOUNT OF WATER COOLING FOR SEAM WELDING?

Yes, water temperature and volume are important for the performance of seam welding. The importance of water cooling the machine components was discussed in this referenced article. This would include the conductors, transformer and the control. The amount of flow is specified by the machine builder. The weld wheels are cooled through their attachment to the water-cooled shaft. The amount of water is frequently specified as 1 – 1.5 gallons of water per minute for these components. Each frequently has its own water circuit originating from a common water manifold to insure flow to each component. These flows cool the components for the current they carry. The temperature of this cooling water is normally city water or cooling tower temperatures which can vary from winter to summer. In extreme cooling requirements a chiller may be required. If these components do not have the proper flow or temperature water their long-term performance will be impacted.

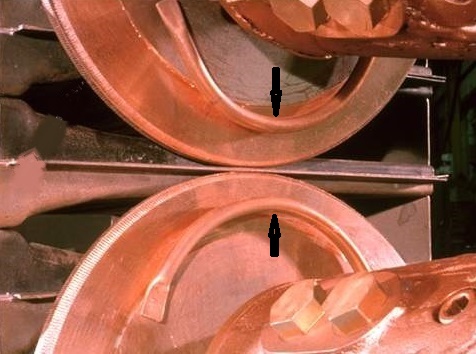

The actual heat generated at the faying surface of the weld zone also needs to be addressed. This is especially true in liquid tight seam welds, where there is very little off time between welds. In this case to cool the weld zone and the weld wheel face flood cooling is employed. Water is sprayed directly on the weld area from water tubes.

SEAM WELDING WHEELS & WATER COOLING TUBES

This water is sometimes recaptured, recirculated and reused over and over. Depending upon the total volume of water in the recirculation system, it could heat up in the course of the day. Warm water is not necessarily bad but if it is too hot for people in the area, it is too hot for flood cooling. A larger reservoir or a cooling system for the flood recirculating system will be needed.

Without the proper flood cooling the weld zones would not cool properly under the wheel pressure. The weld wheels would have excessive wear and mushroom just as spot welds do. The result is loss of control of the process in high heat generating seam weld applications, if not properly cooled.

Reference: RWMA – Resistance Welding Manual Section 4