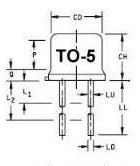

TO-5 cans are hermetically sealed metal transistor assemblies. The leads exit the package through glass insulators. The bottom plate is assembled to the can by forming a continuous ring projection weld around the lip of the lower plate.

It is important not to damage the glass seals on the leads during assembly. Damage to the glass seals will occur if heat or distortion reaches the area of the glass to metal seals.

To prevent damage the following can be addressed:

First: Design the electrode to insure that current flow does not flow through the glass area of the lower plate. Keep the current flow in the periphery.

Secondly: It is important that the tooling be aligned to bring the full periphery of the part in full contact at the same time to prevent distortion of the lower plate. If the plate distorts the glass seals likely will fail and crack.

Third: If the machine does not have proper follow up – as the projection start to collapse the upper cylinder must maintain full direct force on the part. If there is a delay the full force could come after the nugget is cooling and distortion may occur. Again the plate may distort.

Fourth: The bottom electrode should support the full bottom plate to prevent the possibility of distortion. The current will flow in the periphery while the rest of the plate is supported. This helps to maintain flatness and keeps the glass to metal seal areas cool.

Fifth: Both upper and lower electrodes should have some form of cooling.

Electrode material selection – RWMA Class 2 would be the first choice. If it wears faster than desired then go to RWMA Class 3. I don’t think this application would need RWMA Class 11 which would be the next step up in wear resistance.

For additional information see ARTICLE:

ARE THERE ANY CONCERNS USING DISSIMILAR ELECTRODE MATERIALS TO WELD TO-5 CANS?

Reference: CMW Inc. Catalog

Tuffaloy Products Catalog

RWMA: Resistance Welding Manual, 4th Edition, Section 3