Cross wire welding is a form of projection welding. When two wires are crossed that is a point contact. The heat and force are concentrated at that point contact. Even welding a wire to a sheet is a projection weld concentrated in a line point contact. Weld schedules are available in the literature for this type of operation.

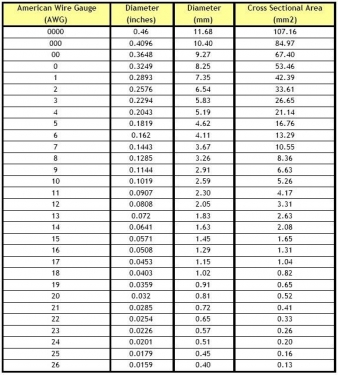

The American Wire Gage Chart:

Knowing the wire size one can look up a possible weld schedule in:

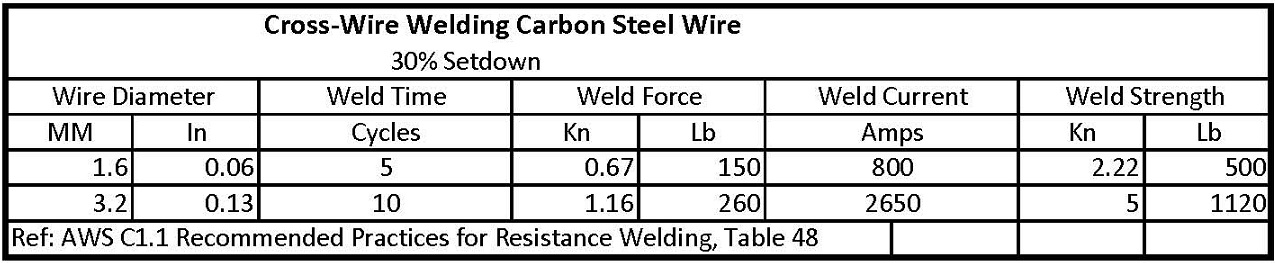

AWS Standard C1.1 Recommended Practices For Resistance Welding

This standard gives an option for 15, 30 or 50% set down of the part. Set down is the amount of loss of height during the welding operation. The welding standard for your operation will determine this value. If one is welding a wire to flat sheet one may want to use the values based on 15% set down.

Below is an excerpt of values for a 30% set down at near 9 gage.

These values do not match the size for 9 gage exactly but they point the way for a starting point. Always start at low power levels and work up over several trials and error. This prevents damage to the product, equipment and people nearby.

Additional data is available in the referenced AWS document.

If welding galvanized or coated wire some expulsion may occur and the current levels required will be a little higher than those for bare metal.

Reference: AWS: AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA: Resistance Welding Manual 4th Edition