Resistance welding weld nuts is a projection welding process. In projection welding the part has been formed by design or shape to deliver the force and current at predefined generally small points, shapes or circles. In the case of weld nuts the power is delivered through several small points. Each projection will develop a normal weld nugget. This form of resistance welding uses the part to concentrate the heat and force not the electrode.

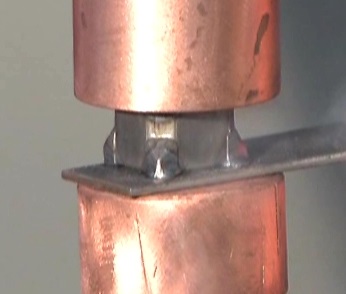

Due to this unique design feature the size of the electrode is not a factor. The electrode is normally flat and at least the size of the part mating surface. It should be larger than the projection weld pattern area to prevent heat buildup and provide support to the part. The size of the electrode has little influence on the weld since the projection concentrates the current and force not the electrode. Factors besides the part size that might influence the electrode selection could be: the available equipment, available tooling, expected power requirement and anticipated force. The electrode should be larger than the part being welded as shown.

PROJECTION WELD NUT

In ring projections the electrode diameter should be at least twice the diameter of the projection ring. So the answer is yes it could be a 6 and 8 MM electrode mix is they fit the parts properly. Or two 8MM’ s if you want common electrodes to reduce electrode inventory?

In some welds individual electrodes are used on the one side and a common bar electrode is used on the other side. Fencing can be projection welded in this manner.

Reference: AWS Standard C1.1 Recommended Practices for Resistance Welding

RWMA – RWMA Resistance Welding Manual 4h Edition