This is an interesting question. Most people are concerned about the height of the projections varying or not being present. The flatness of the base metal is considered a given. Any variation in the projection or the base metal that creates the same gap can lead to a welding issue. The question is how much gap can be tolerated.

After the force is applied before the current is initiated full projection set down is needed to eliminate all gaps in order to prevent material expulsion and maximize weld strength. Gaps in a ring projection or multiple projection all have the same requirement for flatness. Flatness helps to make complete set down and full contact to ensure the current is evenly conducted through all of the projection areas at the same rate. This will maximize nugget formation as desired either as a ring, single or multiple projections.

A search of the literature found one source that listed allowable tolerances for projection heights.

AWS C1.1 – “Recommended Practices for Resistance Welding”

Table 46 listed a height tolerance up to: +/-1.27 mm (+/-0.005 in) for material over 1.27 mm (0.050 in) thick.

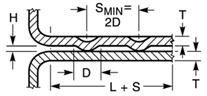

PROJECTION HEIGHT "H"

For thinner material and complete information consult AWS C1.1 – “Recommended Practices for Resistance Welding."

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA - Resistance Welding Manual 4th Edition