We will talk about the weld schedule first. There is no formula for a weld schedule. If you know a schedule for a similar single projection weld it can be applied to your application. If you are welding several projections of the same size and they are spaced modestly multiply the current and force by the number of projections. Current and time stays the same.

Ref: Blog article:

HOW DO YOU DEVELOP A PROJECTION WELDING SCHEDULE?

If a weld schedule is not available then references are available and are listed in the above article. Additionally the references listed below have weld schedules for projection and spot welding various thicknesses of materials.

A spot weld schedule can be used as a starting point. The multiplier noted in the above article will apply applies here.

Remember always start your set up with the power on the cold side to avoid any major expulsion. Then adjust the power up slowly.

When you have achieved a weld nugget it is measured just as in spot welding:

WHAT IS THE FORMULA FOR CALCULATING A WELD NUGGET?

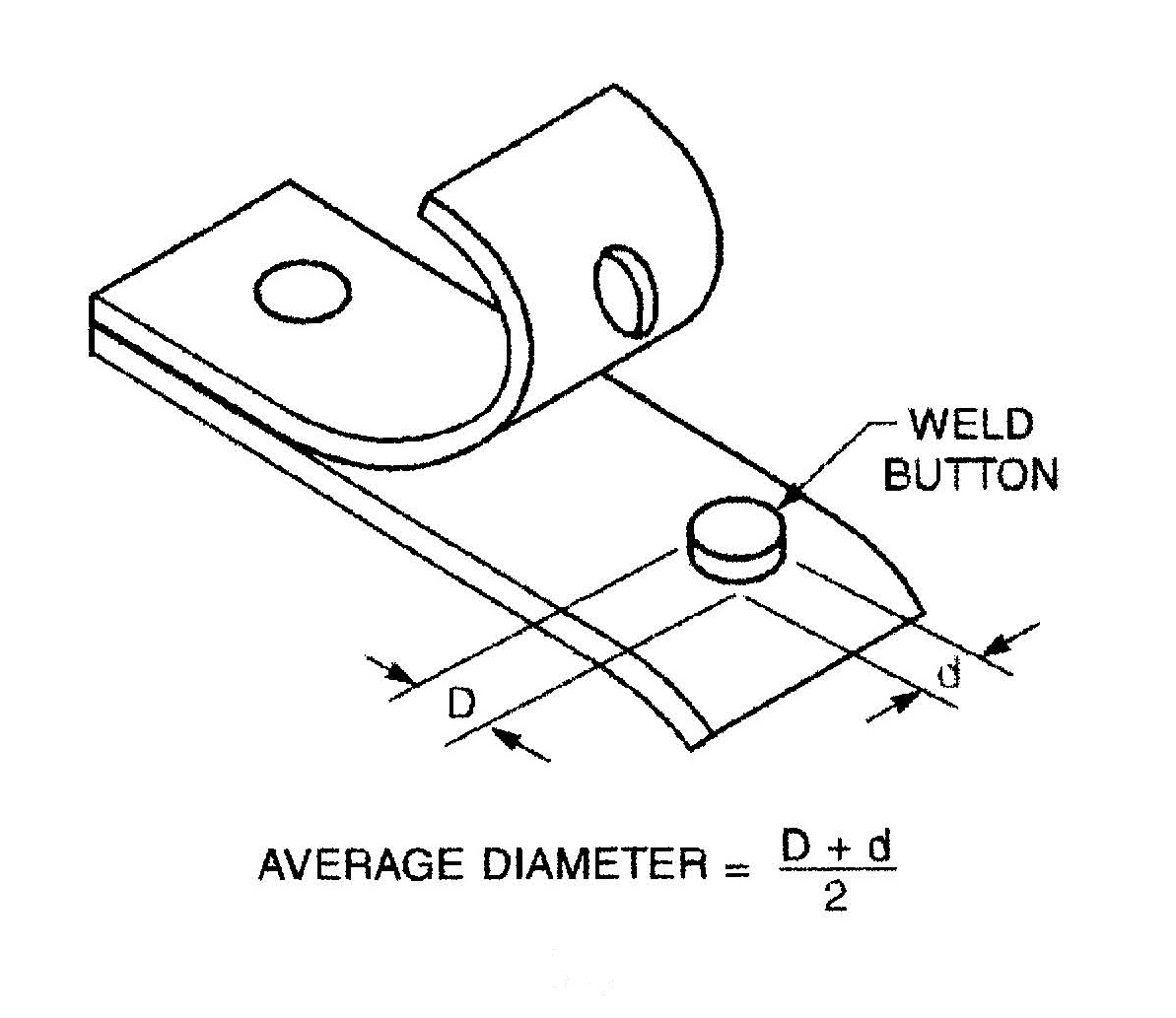

Measure the nugget in two directions at 90 deg apart. Average the two values and you have the answer.

WELD NUGGET CALCULATION

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition

Tuffaloy Product Inc. Catalog

CMW Inc. Resistance Welding Products Catalog