The answer to this is there is none. One can measure a weld nugget after it is made. One cannot calculate a weld nugget in advance, since one has not preset any of the variables of the process. The simple variables are squeeze, weld and hold. They quickly expand into force/pressure, electrode material, electrode wear and face size, coating pick up on electrode face, material being welded, surface condition, coating and on and on. There are many more but we will stop here. All of these variables will influence changes in the weld schedule that will directly change the size of the weld nugget.

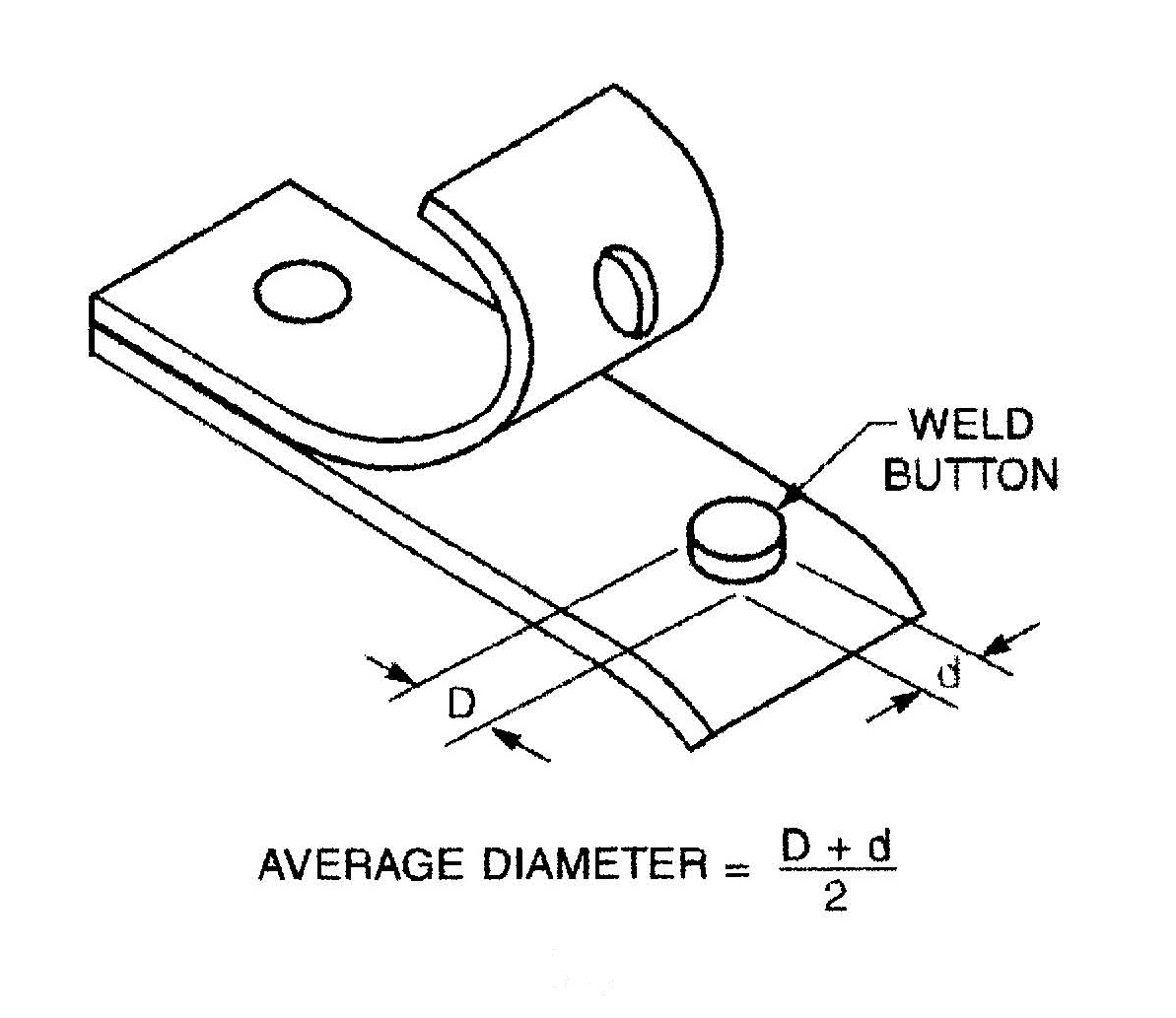

The resultant pulled weld nugget is measured with a set of calipers in two directions, 90 degrees apart.

This is how to measure a weld nugget.

No one has the ability to predict with calculatable accuracy what nugget size a given set up will produce.

AWS C1.1 Recommended Practices for Resistance Welding

AWS C1.1 lists many weld schedules capable of producing weld nuggets at the conditions specified. These standards were not calculated but they will produce welds nuggets using the weld schedules listed for many common materials and processes.

Ref: AWS C1.1 Recommended Practices For Resistance Welding