Yes, non-cast wheel rims are made by flash welding. The work acts as the electrode and the entire cross section is welded. The parts are clamped and brought close together. Force is not applied and the current begins. The intent is to strike an arc between the two surfaces. This resultant arc heats and by removing the surface material in the flash cleans the mating surfaces and prepares them for bonding. At the proper time force is applied and the arc current is removed. The surfaces come together and the heating may continue with standard Joules Law heat H= I2rt heating at the joint. The metal upsets and a joint is formed. The current is turned off and cooling begins. When cooled, force is removed and the part joint is complete and ready for slag/flash removal.

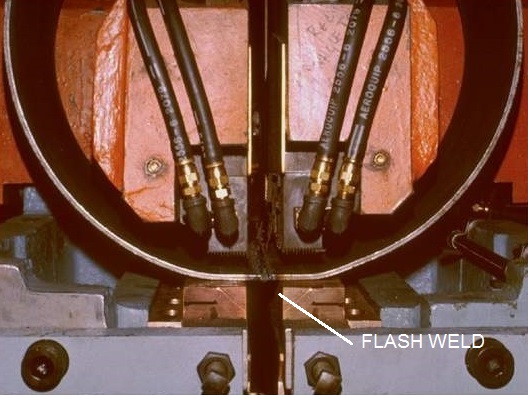

Flash Welder

This is a very fast and reliable process. These joints must be air tight after being formed into the stepped shape of a wheel rim. We all drive on these wheels and rarely have a leaky rim.

Reference: RWMA – Resistance Welding Manual Section 5