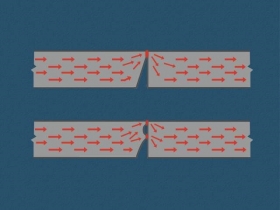

Flash welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. The parts are clamped and brought close together and a current is applied. The current creates an arc between the work pieces and heating begins as well as expulsion. Force is applied. The parts come together. The arcing current is removed. The parts joint is upset/forged to the desired amount. The part is cooled and the force is removed. The resultant flash weld has weld flash around the weld area which is usually mechanically removed. The resultant welds are very strong and fluid tight. Wheel rims are manufactured using this process and are very reliable. The rims do not leak air on our cars and trucks.

Reference: RWMA – Resistance Welding Manual Section 5