Flash and butt welding both use the work piece as the electrode. They both use a clamp to hold the parts and apply force. This clamp carries current so it must conduct current and dissipate heat. This makes copper alloys a first choice. In many cases the Group A copper alloys will be used for this application. If mechanical wear is an issue Class 3 might replace Class 2.

These clamps frequently will be small inserts in the jaw for easy replacement or redressing. Group B materials are often used for increase life. They are always used as an insert.

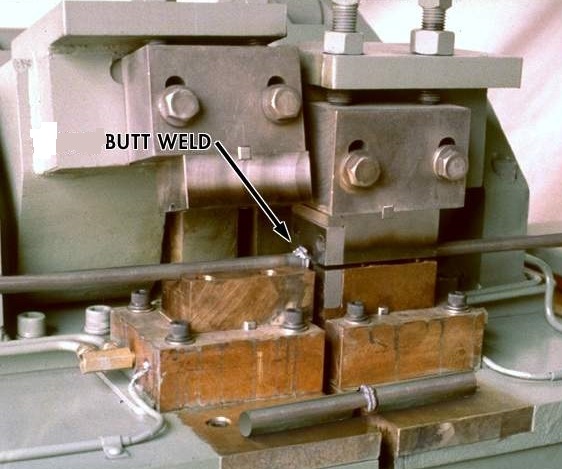

Butt Welder with Replaceable Clamp Insert

Reference: RWMA, Resistance Welding Manual, Section 5