Butt welding is a joining process used to join two parts together. The work acts as the electrode and the entire cross section is welded. After the parts are clamped and brought together with force a current is applied. The intention is to create heat using Joules Law H= I2rt at the joint surface with current flow.

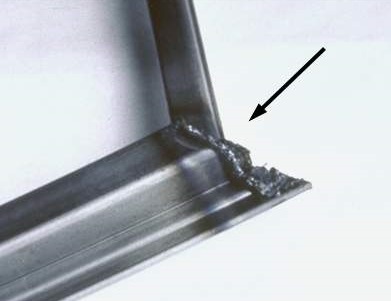

As the joint heats up the force upsets the joint and a bulged area is formed. The current is stopped. The weld area cools under force and then the force is removed and the butt weld is complete. This differs from flash welding, where the current is applied before the two pieces come together. This creates the flash.

Rods are welded end to end and then drawn into large wire coils using this process. It is fast reliable and repeatable. The bulged/upset material is normally removed by mechanical means. Grinding tools or files are frequently used for this.

BUTT WELDED AUTO DOOR FRAME

For additional information on this subject read another article in this blog:

WHAT IS A FREQUENTLY USED BUTT WELD PROCESS?

Reference: RWMA – Resistance Welding Manual 4th Edition, Section 5