The person making this inquiry has seen this finished product and questioned is it better to butt welded before or after the plating process?

A second question was could equipment be fabricated in house to perform the butt welding?

It is this authors belief never having seen this product, that the plating process is a post welding operation. Butt welding and the generated heat would severely distort physically disfigure the area of the butt weld. Material removal is likely required to resize the butt weld/upset area. Any pre butt weld plate and diamond in that area would have been ruined. If nickel plate is necessary in this area, at least a spot replate could be performed. The diamond would be missing for this short length.

It would be assumed this diamond tipped wire is being used to cut through some very difficult/hard materials and coolants will likely be present. A short welded length may not be a problem.

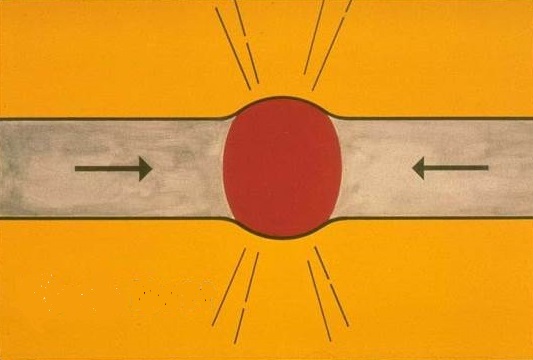

BUTT WELD

Building equipment with the precision to butt weld material 0.010 inches (.25mm) in diameter is no small task. Alignment, movement and power control would be critical and certainly beyond the scope of this blog. It would be a job for a company that specializes in working with smaller products.

Reference: RWMA – Resistance Welding Manual 4th Edition