Yes, 12 mm (0.472 inches) Cadmium Copper rod can be butt welded. However safety must be considered with this material. OSHA regulations and cadmium's listing as a carcinogen have restricted the manufacture of this material in many parts of the world including North America.

In previous decades it was manufactured as rod and wire and was butt welded successfully. It was butt welded to make longer lengths in the various mills for drawing into wire coils. Any use of this material that could generate cadmium fumes in the work environment might need to be engineered properly to protect the personnel and the environment.

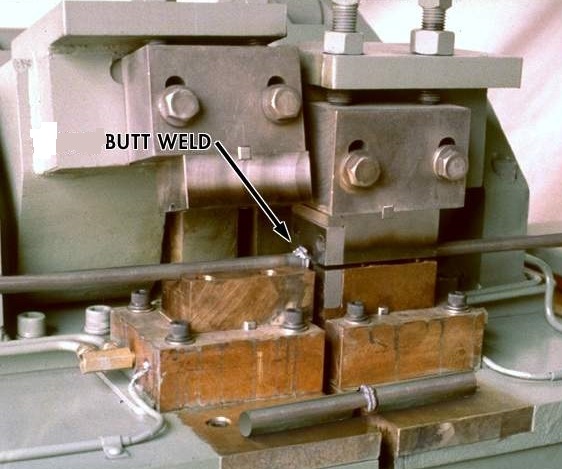

Butt welders are being used in industry to join copper alloy rods of this size in industry every day. Any butt welder manufacturer can develop a machine and process that would be suitable to butt weld this material provided that your OSHA/Safety laws permit its manufacture.

Rod Butt Welder

Butt welding rod end together is used to make long rods or coils in a metal rod or wire mill. As each butt weld is made the resultant flash or upset material is mechanically removed for ease of drawing through the draw die. Multiple rod ends are welded end to end and then drawn through a draw die to size the rod to a slightly smaller size. It is frequently coiled on a coiler as it is drawn. When the desired numbers of rods have been welded together, the resultant coil is then drawn through a series of smaller dies until it is at the desired finish size. This is how rod is turned into a coil of wire. The welds are fast reliable and repeatable. The butt welds are virtually indiscernible.

Reference: RWMA – Resistance Welding Manual Section 5