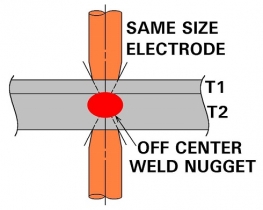

Poor heat balance in a resistance weld is when the variables cause the weld nugget to form in a location other than the desired mating/faying surfaces. This can be caused by welding two different materials, varying thicknesses, or different surface coatings. Different electrode material, size, shape or contact face or perpendicularity to the part. Water cooling or lack of same can cause variations also. The first step is to examine the part and determine what is causing the nugget to form in this undesired location.

This example exhibits two different thicknesses of material which will cause the nugget to form on the thicker side of the part. This condition can be improved by using a larger faced electrode on the bottom to spread the heat out and cool that side. The nugget will move up and into the faying surfaces. As an alternative more conductive electrode materials can be used on this hotter side to cool it down. Conversely on the upper side the opposite would help smaller weld faces or hotter less conductive electrode materials will draw the nugget up to the faying surface.

No matter what the cause for the poor heat balance the correction is made by moving the heat to where you want it by cooling one side or heating the other side of the part to counteract the situation and move the nugget to the faying surface.