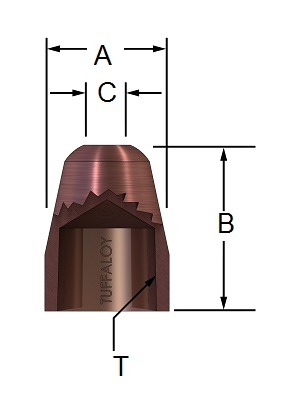

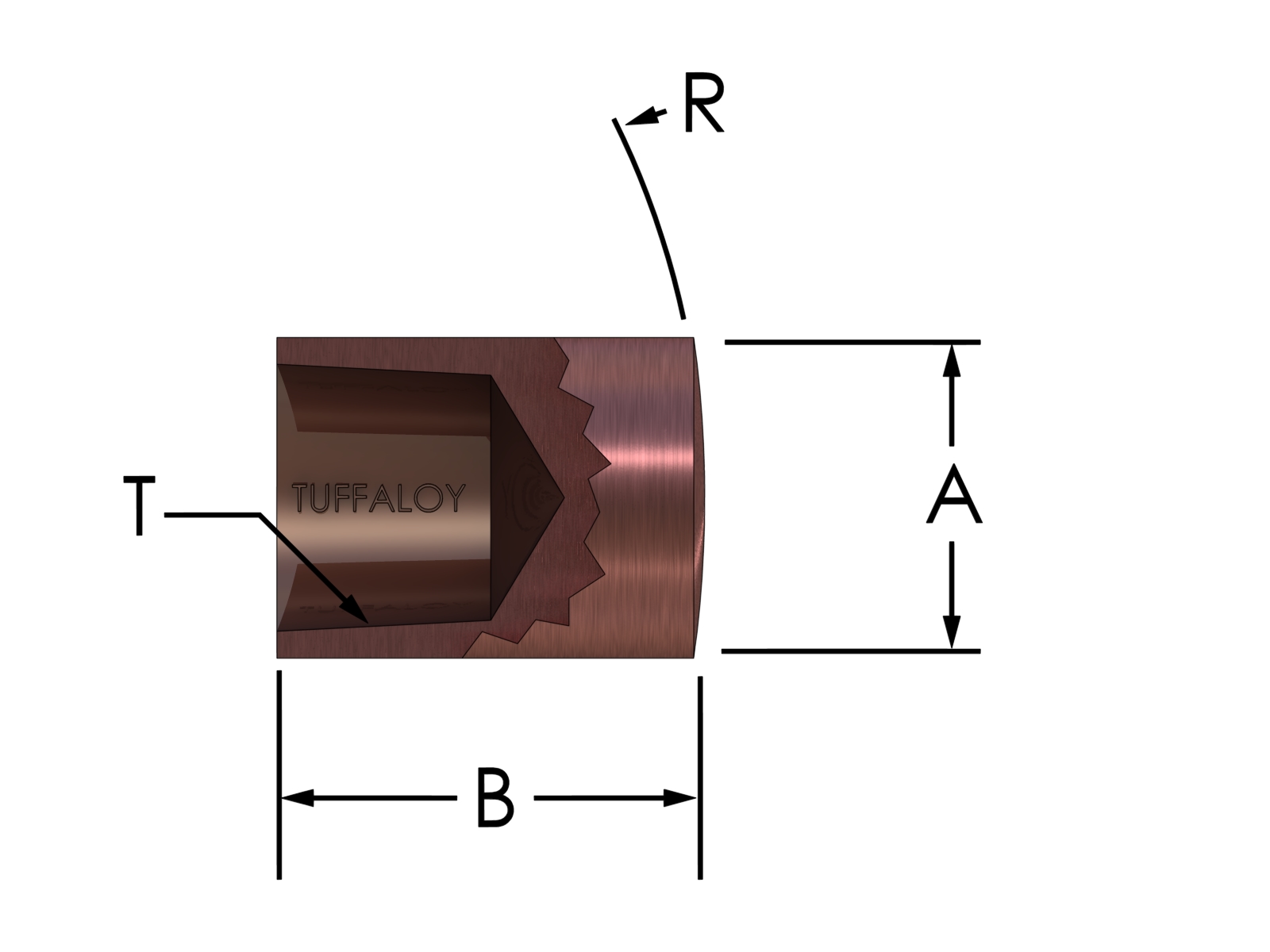

There are six standard faces designs. Shown below are female caps. The same face designs are offered in male caps and full size electrodes.

A-Pointed B-Dome C-Flat D-Offset E-Truncated F-Radiuis

The proper choice of electrode face design will depend upon your application, the material being welded and resistance welding process. If Spot welding, you might use any of the six standard designs. The “A”, “B”, “D” and “E” faced electrodes all have the same weld face if purchased in the same body size. The “C” is a flat faced electrode and the “F” is a full large radius electrode which almost appears flat.

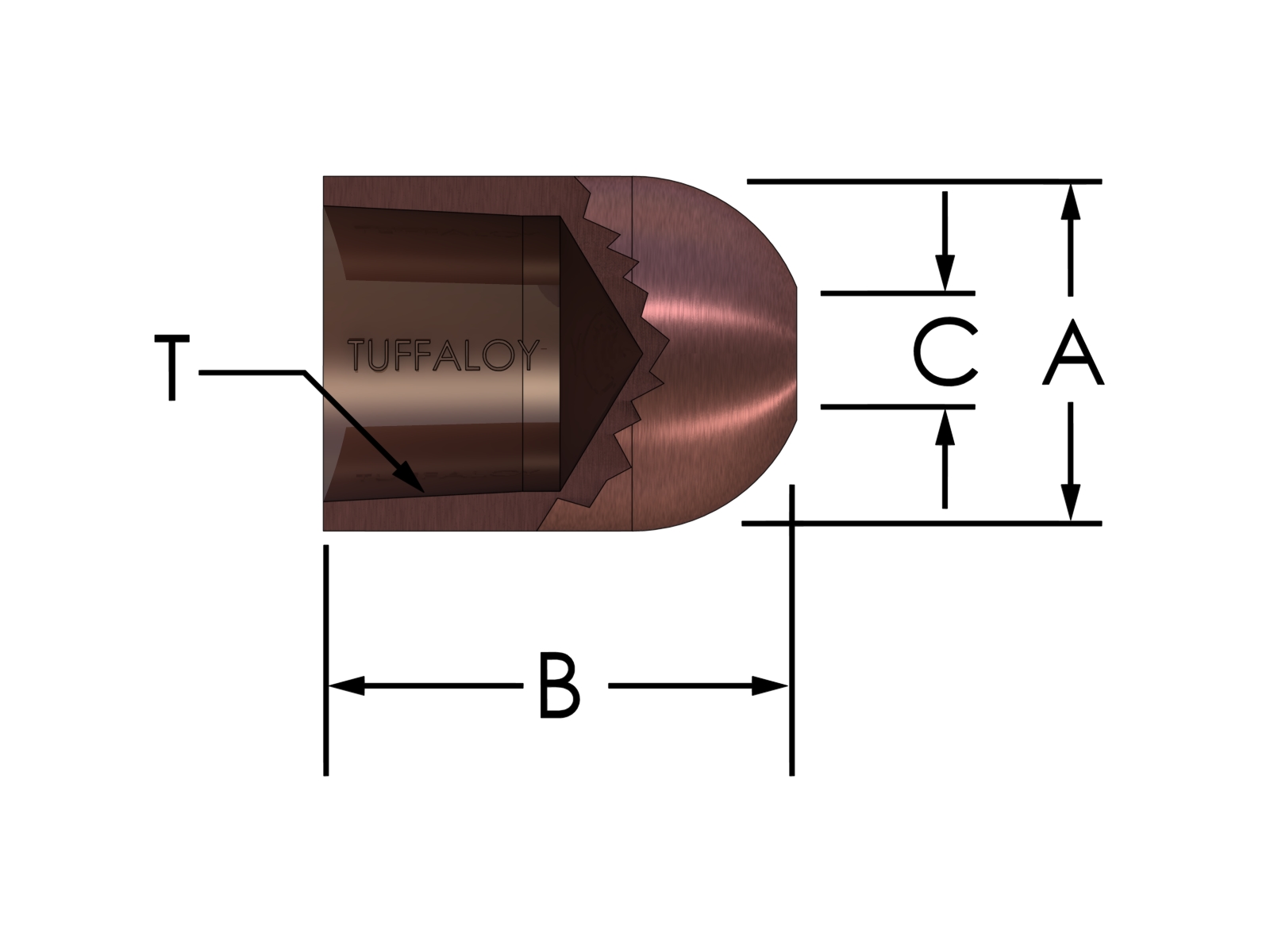

The “A” pointed nose is a good general purpose weld face suitable for most spot welding applications. It is a big user in industry.

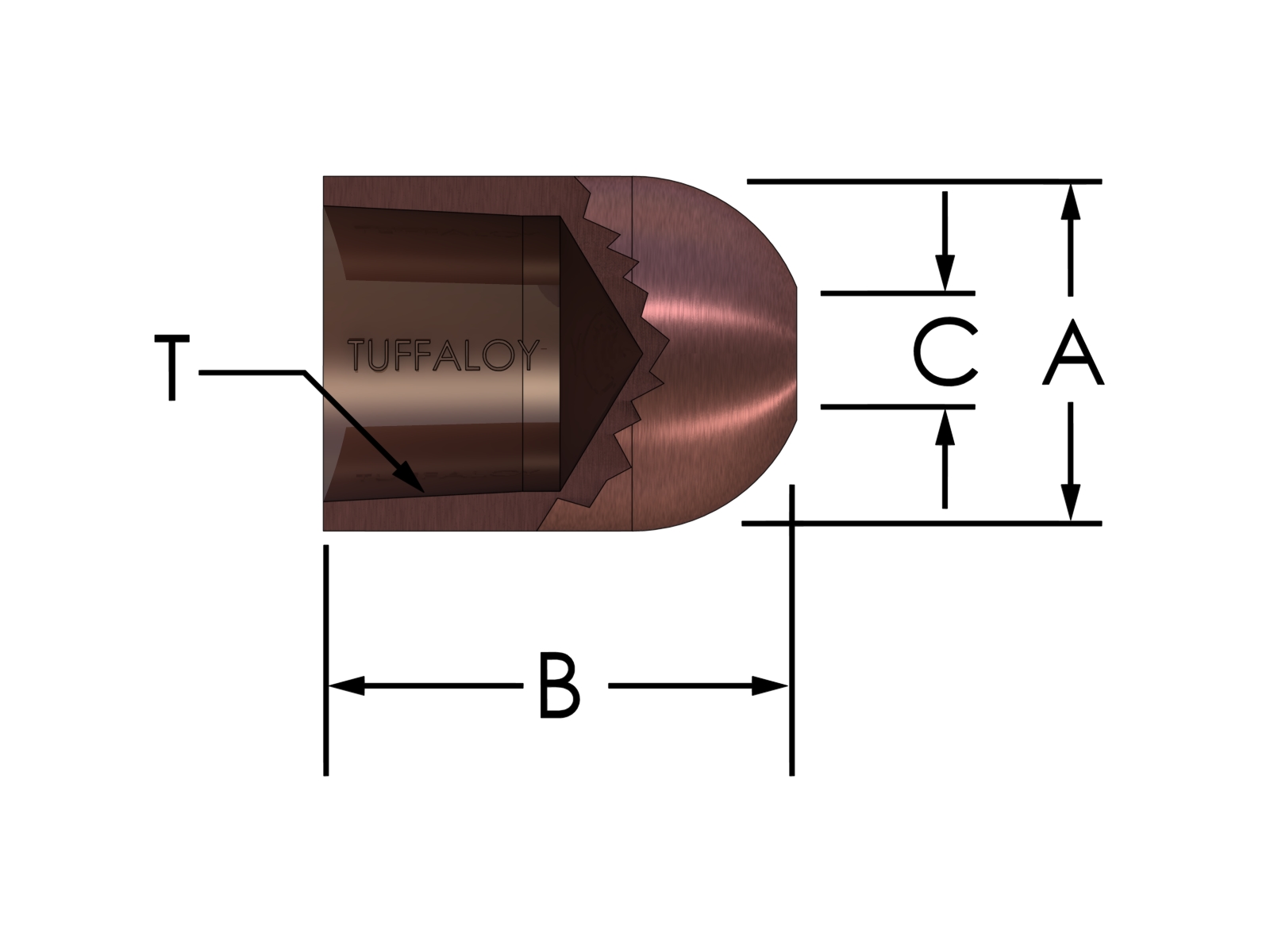

The “B” Dome nose has a radius. It is a very efficient electrode. It is sometimes used to allow for misalignment problems. If two radius electrodes meet on a radius, it will be a point contact and quickly form their own new weld face. The “B” is offered with a flat weld face or a full dome. It is the most popular/highest used electrode in weld cap form.

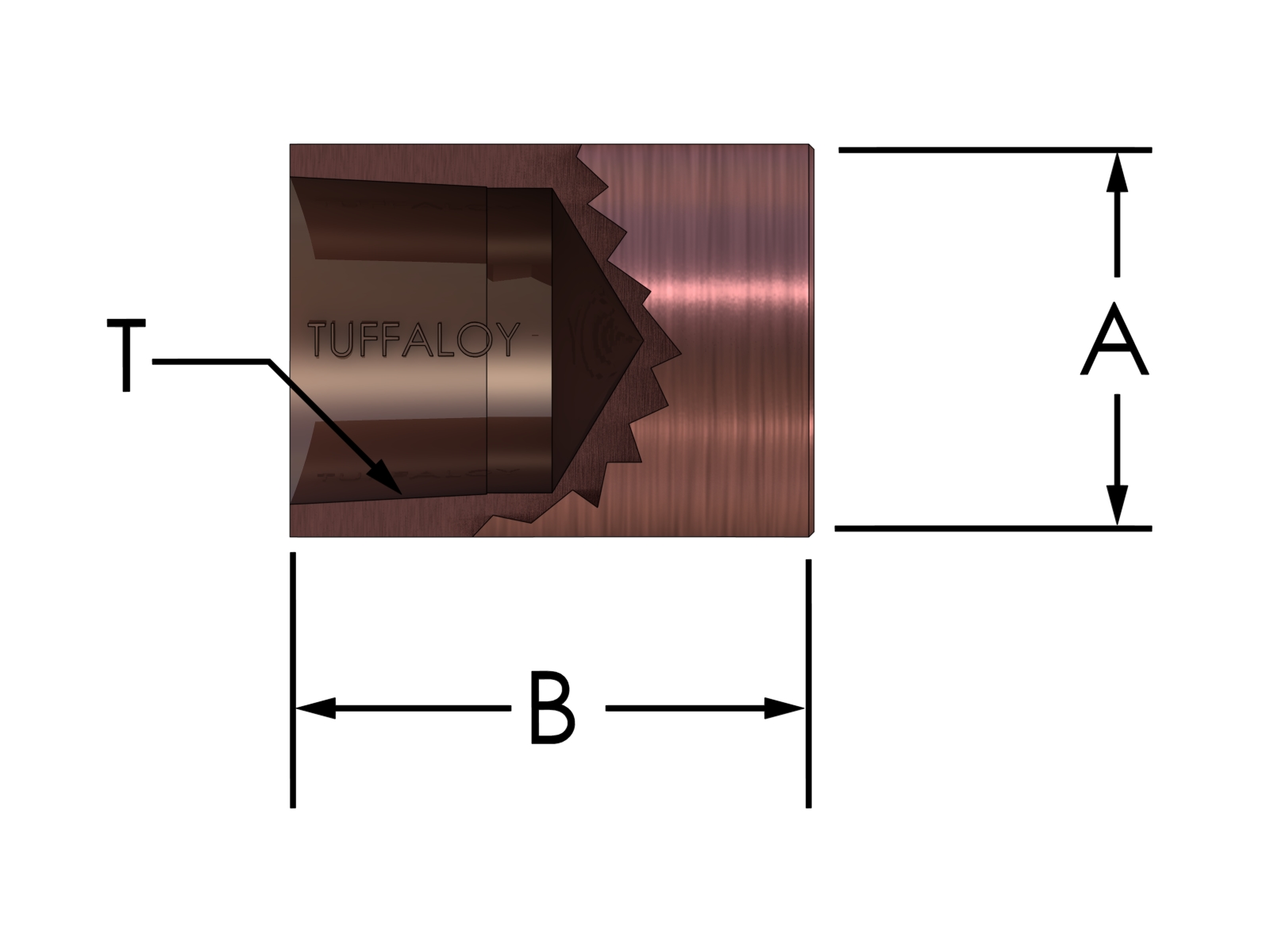

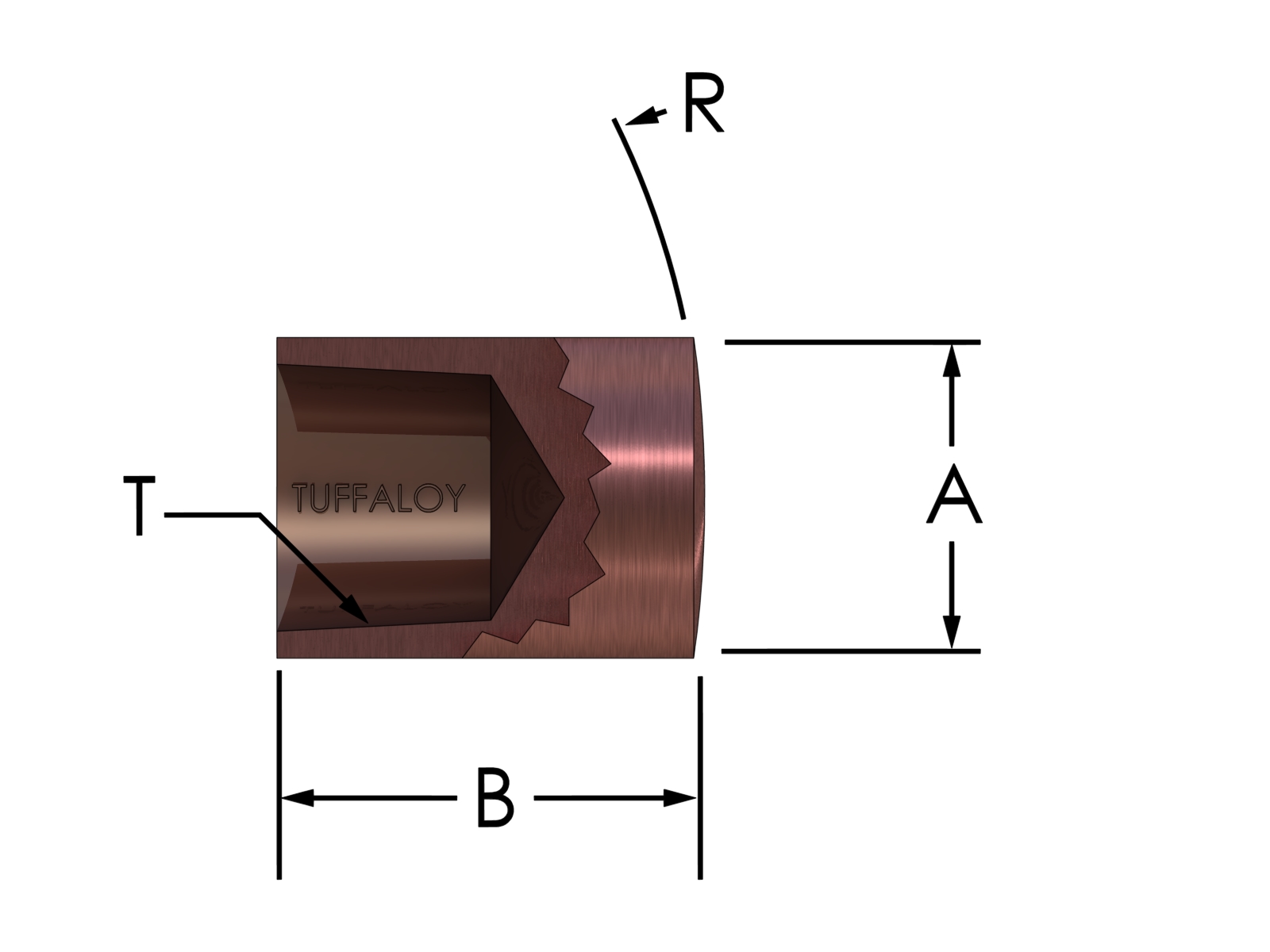

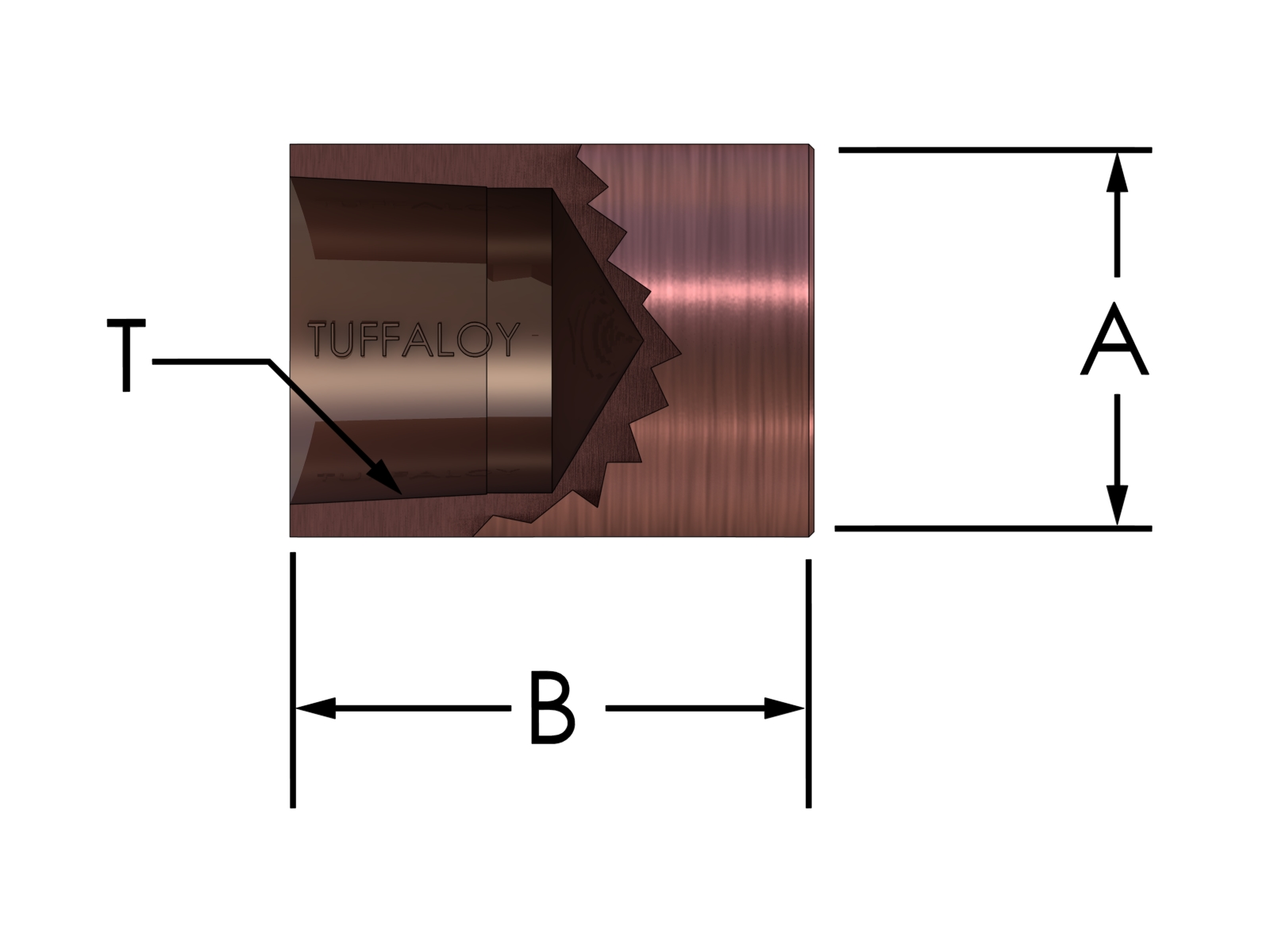

The “C” Flat face is frequently used as a back up electrode for projection welding. It also is used for cosmetic welds and heat balancing. The use of the “C” face on one side of the weld reduces the indentation thus producing a cosmetic weld by spreading the force and current on that side over a larger area. In the case of heat balancing the “C” flat face is used to spread the current out over a large surface area. This spreads the heat affected area out and reduces the heat on that side of the part. The goal of heat balancing is to reduce weld nugget penetration on that side of the part.

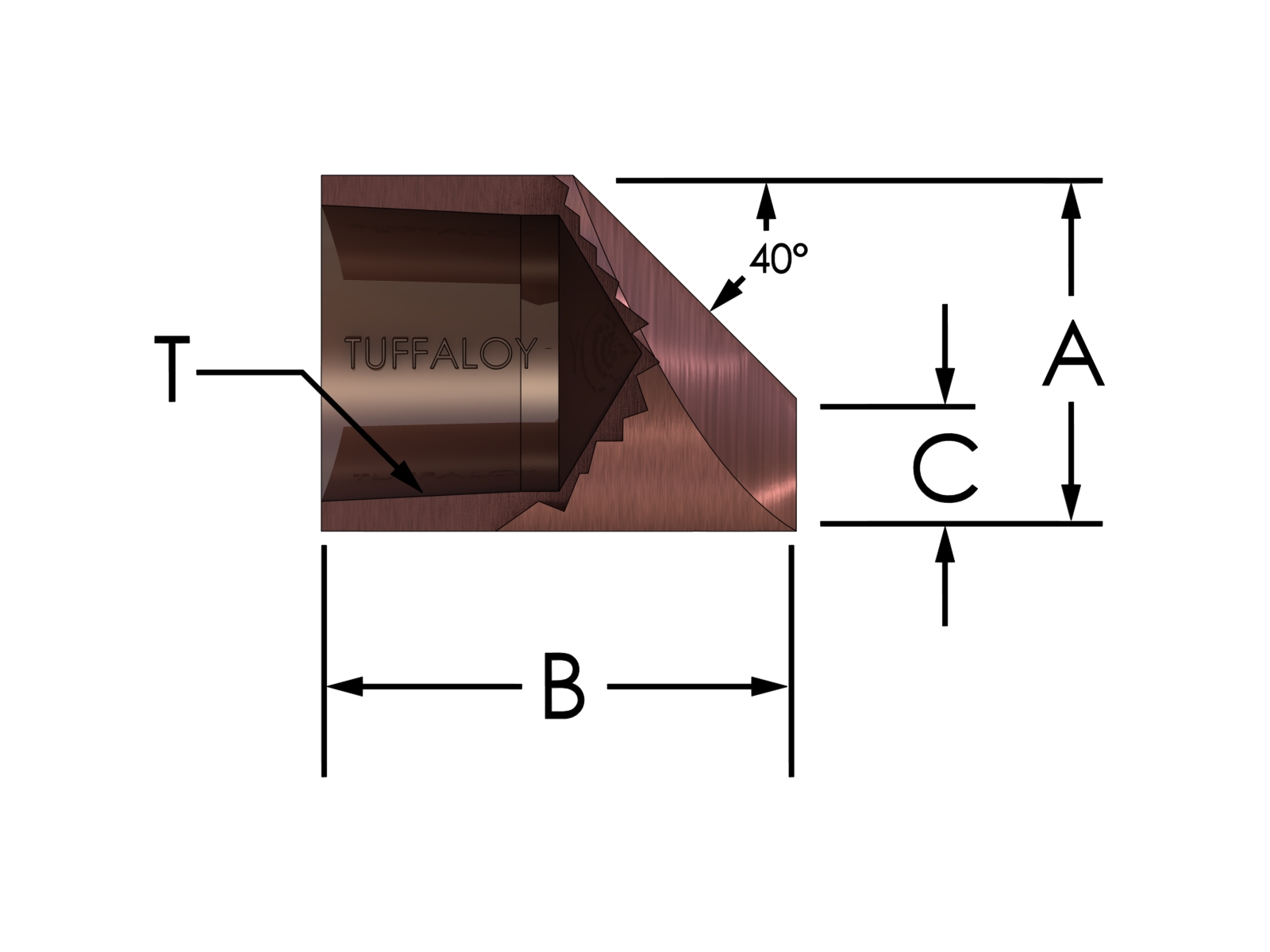

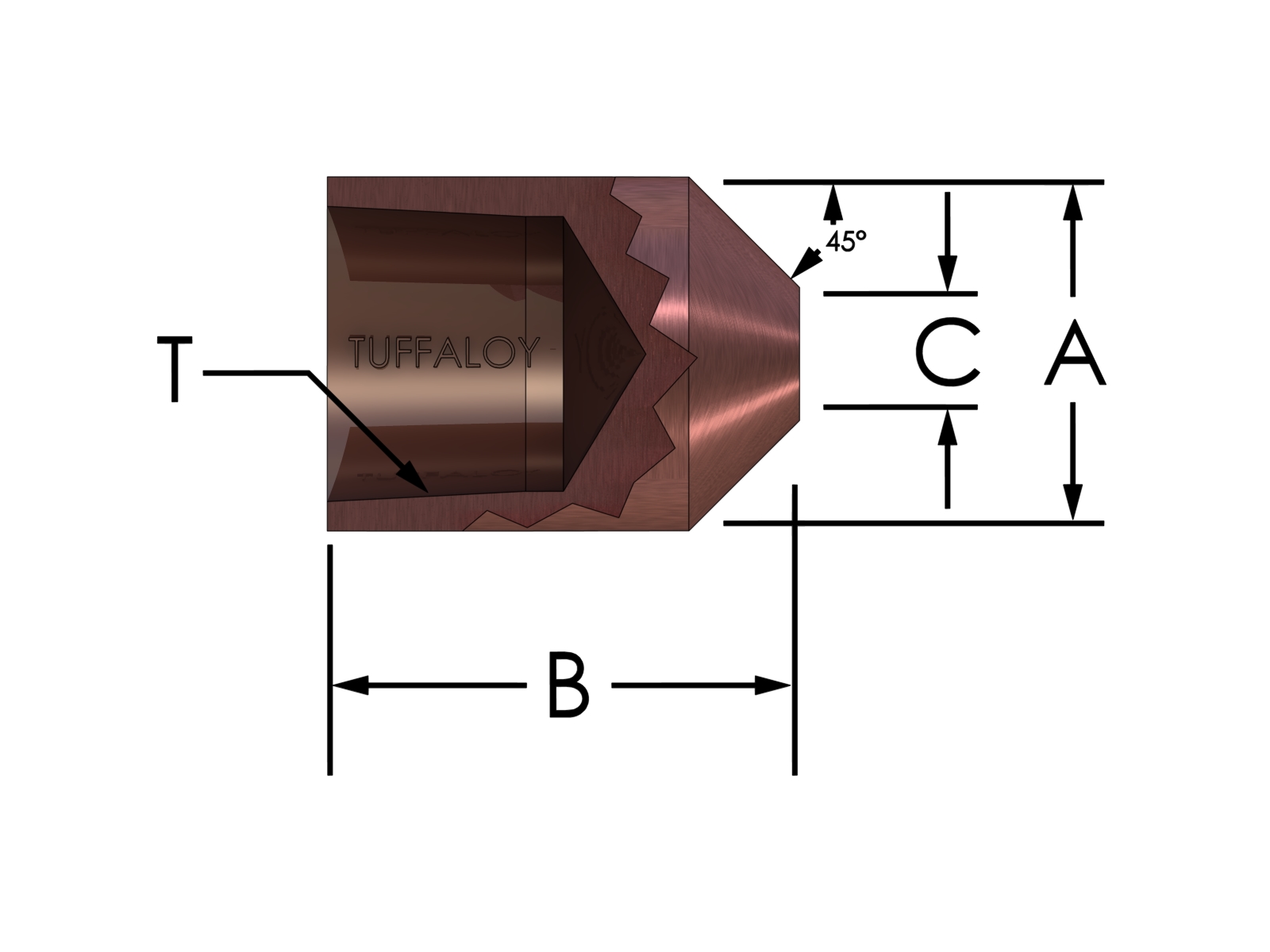

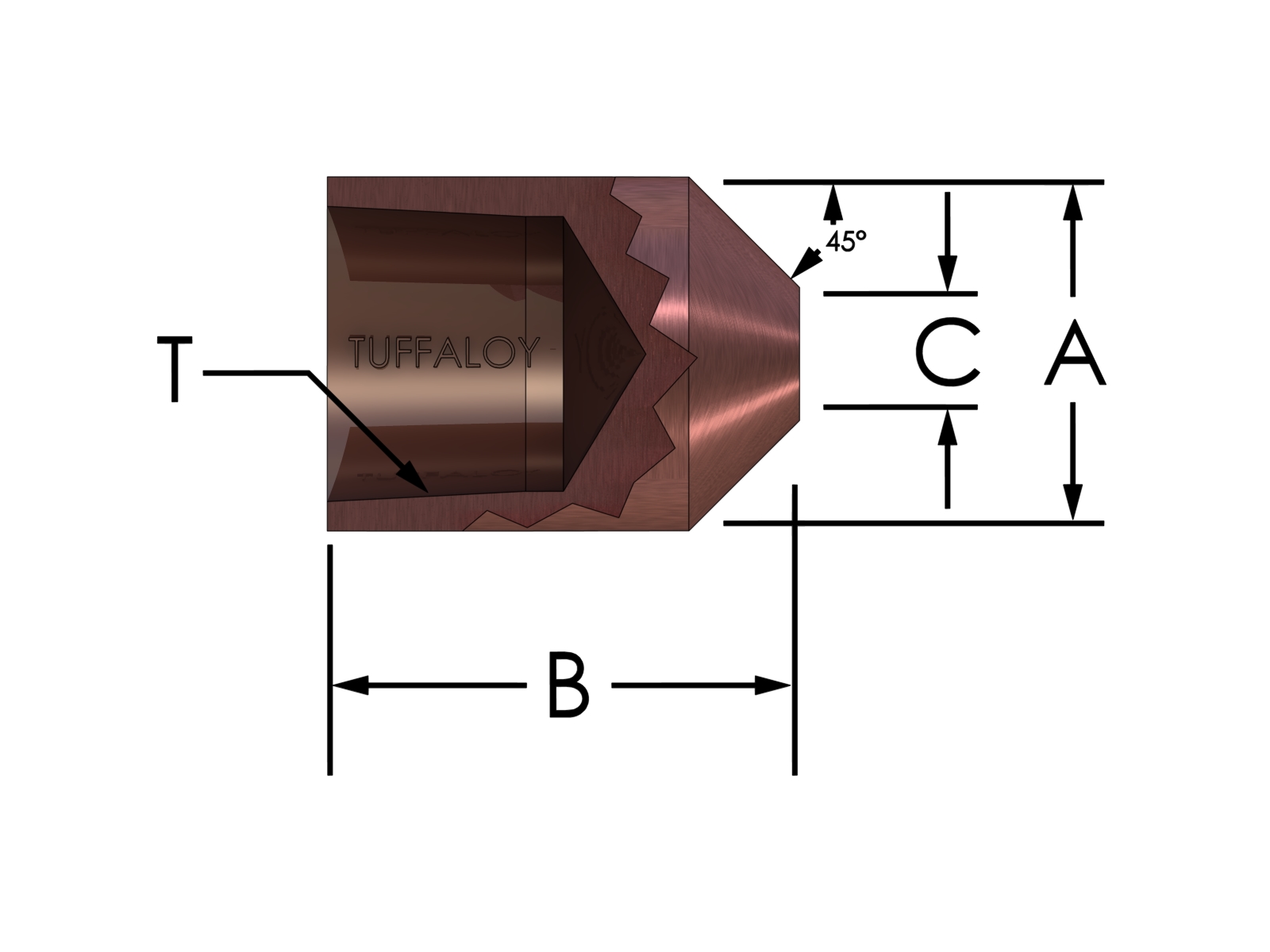

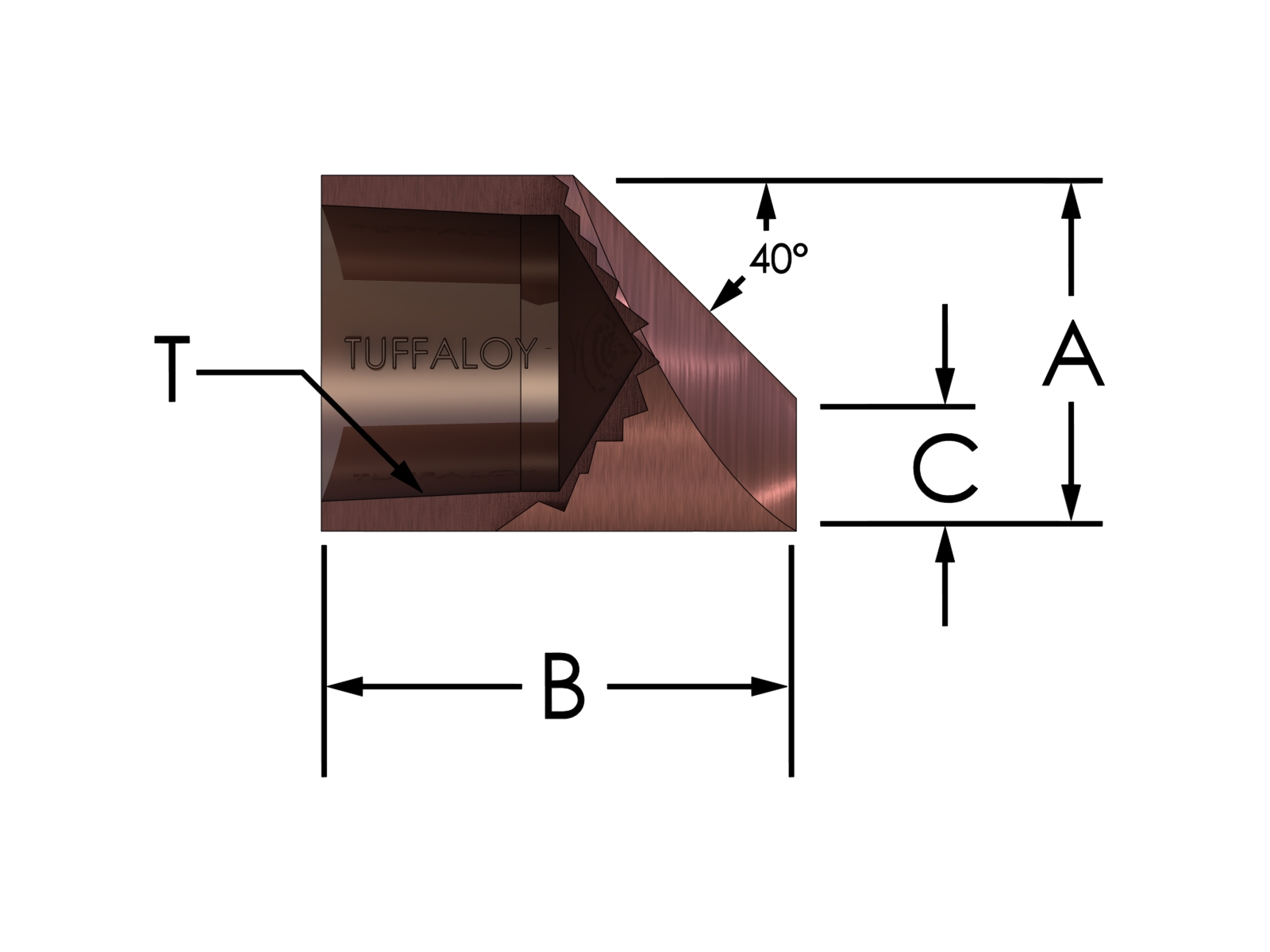

The “D” Offset nose is designed to be able to put spot welds in tight places. This could be a small flange or in a tight corner. Orientation of the electrode is necessary during set up to take advantage of this feature.

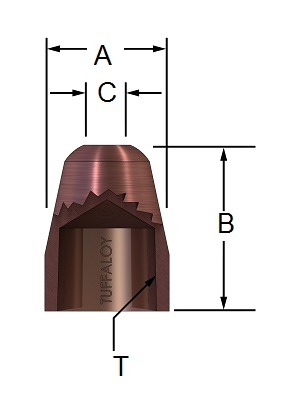

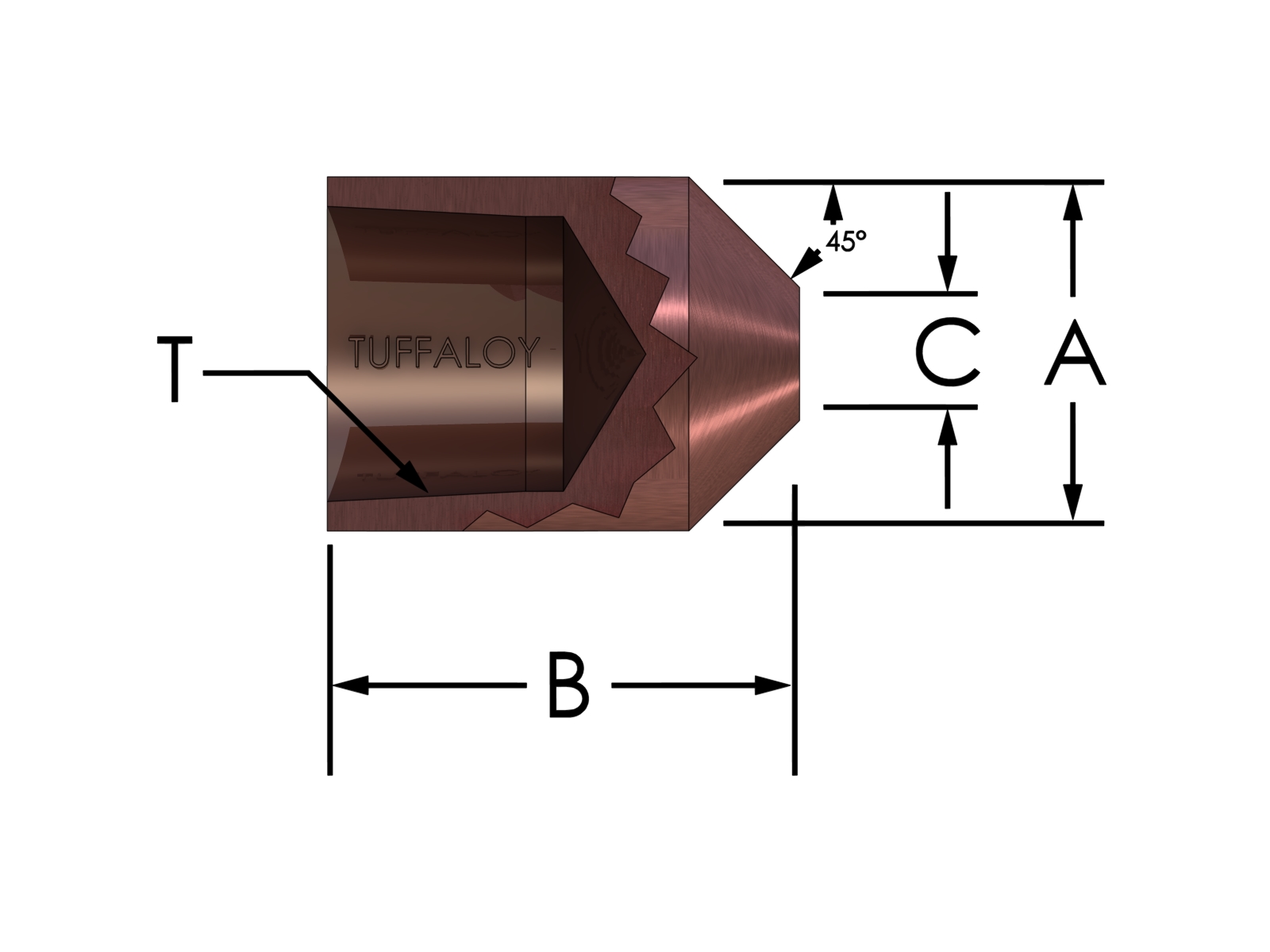

The “E” Truncated nose is a very efficient electrode that tends to not trap weld flash on the weld face and may lead to slower mushrooming. It is used often in industry.

The “F” has a large radius face and is frequently used to weld aluminum. The large radius provides a good point contact to break through the aluminum oxides and still provide adequate surface area to control the weld nugget during the weld sequence.

For additional electrode design information consult with your electrode supplier or reference the Resistance Welding Manual published by RWMA/AWS.

Reference: RWMA Resistance Welding Manual 4th Edition