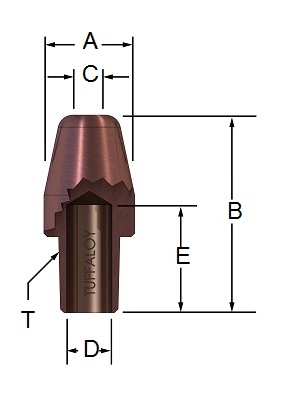

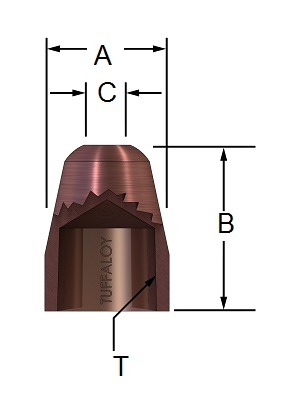

Electrodes are available in many sizes and shapes to fit most needs in industry. To choose many considerations come to mind. The first decision would be full size vs cap electrode. Are you a job shop or highly automated usually decides this.

FULL SIZE AND MALE CAP MALE CAP FEMALE CAP

The next question might be Female vs Male Cap Electrode. This is more complicated. They both work well. The decision may come down to the ongoing which is better a Chevy vs a Ford discussion. There is no clear winner or loser.

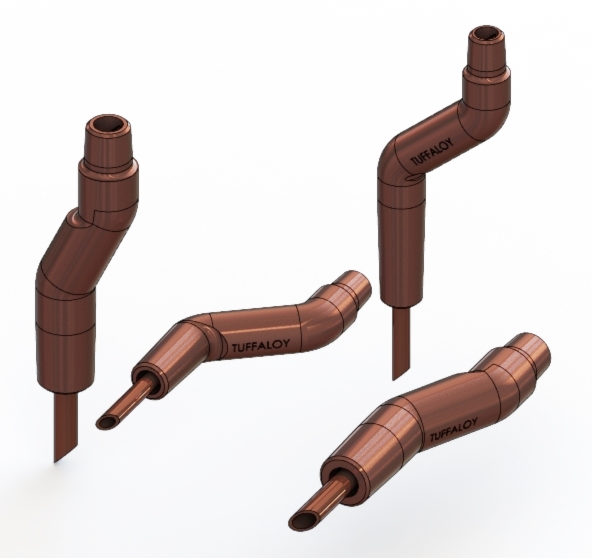

Then there are single and double bend electrodes and shanks. These let you reach into corners and tight locations and maintain water cooling for the electrode.

DOUBLE BEND ELECTRODES DOUBLE BEND SHANKS FOR FEMALE CAPS

Through all of this you must decide electrode size which is determined by the force of your weld schedule and the nugget size desired. If forces are extremely high greater than 2000 lbs, other attachment systems beyond tapers are required and are available.

If you are projection or nut welding, a whole different family of electrodes and holder systems are available.

Many questions must be decided and the answers are available in the Resistance Welding Manual published by the RWMA/AWS. Other sources are your local supplier and their expert knowledge and available catalogs such as Tuffaloy and CMW's.

Articles available in this blog on these subjects are:

HOW MUCH FORCE CAN A RESITANCE WELDING ELECTRODE TAPER WITHSTAND?

WHAT ELECTRODE FACE DESIGN IS BEST FOR MY APPLICATION?

DOUBLE BEND ELECTRODES CAN WELD IN CORNERS OR RESTRICTED AREAS

Reference: RWMA - Resistance Welding Manual 4th Edition

AWS Standard C1.1 Recomended Practices for Resistance Welding