Aluminum is a soft low resistance material. Additionally, it readily forms nonconductive oxides on its surface very quickly. Due to its low resistance high currents are required 30-40,000 amperes. As compared to steel at 10,000 amperes. It melts at low temperatures and has a high coefficient of expansion. Care must be taken to maintain force as the nugget shrinks (fast follow-up) (secondary forge cycle) or voids will be present.

To address sticking, it melts at low temperatures. It requires high currents. High currents through the electrode mean heat and could lead to electrode face pickup and sticking. This must be minimized. Use the most conductive electrode alloy RWMA Class 1. Use a radius face to concentrate the current in a small area for affect. This helps to break through any remaining surface oxides not removed in the recommended aluminum surface cleaning. Additionally the weld should be hot but short. Just a few cycles if AC and a few millisecs if MFDC. The point is to minimize the time of the weld and keep the electrode face cool. The cooler it is the less pick up there will be. Internal water cooling of the electrode is always a requirement.

What I have described is outlined in AWS standard:

AWS C1.1 Recommended Practices for Resistance Welding

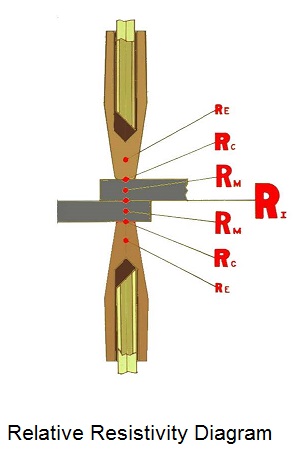

The need is to deliver the proper current but keep the contact resistance low RC

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Resistance Welding Manual 4th Edition