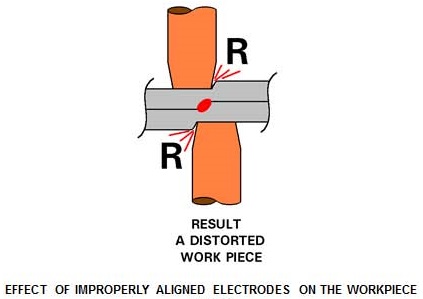

Misaligned electrodes could be because they are not perpendicular to the work piece. Or the two opposing electrodes do not line up with each other as shown below. The first condition can cause the electrode to make contact on the edge of the face rather than the desired face area. This puts a large amount of current through a smaller area. This leads to overheating and expulsion. It also can cause skidding of the electrode on the work surface.

If the electrodes do not line up as shown above the part will be distorted and may be damaged. Electrode wear will be distorted and will lead to skidding and expulsion. In general misalignment will lead to excessive electrode wear and shortened life.

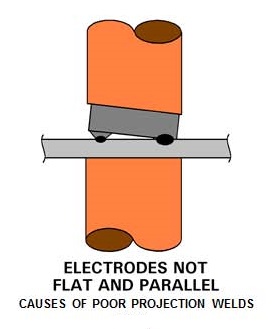

Misaligned projection welding electrodes casue similar problems. If the electrode causes one or more projections to make better or more contact than another the current will flow unevenly between them. The result will be little or no weld on some of the projections. There will likely be expulsion since some projections are carry too much current. Or a projection is not being held in good contact with the part and arcing will occur.