The proper electrode material can be determined from published weld schedules based on the work pieces being spot welded. These weld schedules can be found in AWS Standard C1.1, Recommended Practices For Resistance Welding and RWMA The Resistance Welding Manual. Your electrode supplier is another source. Spot welding requires a few initial decisions to be made to set up a good welding process. Most of these evolve around pressure, current and time.

In addition to these you must select the proper electrode material to use for your application. This material will need to be able to handle the forces and currents that you will be applying in your welding operation. Therefor the electrode material selection is based upon the work piece material being spot welded.

Highly conductive work piece material like aluminum requires high currents for spot welding and therefor need highly conductive electrode material – Class 1. More resistive materials like stainless steel require considerably lower currents but high forces. They are spot welded with stronger material found in Class 3.

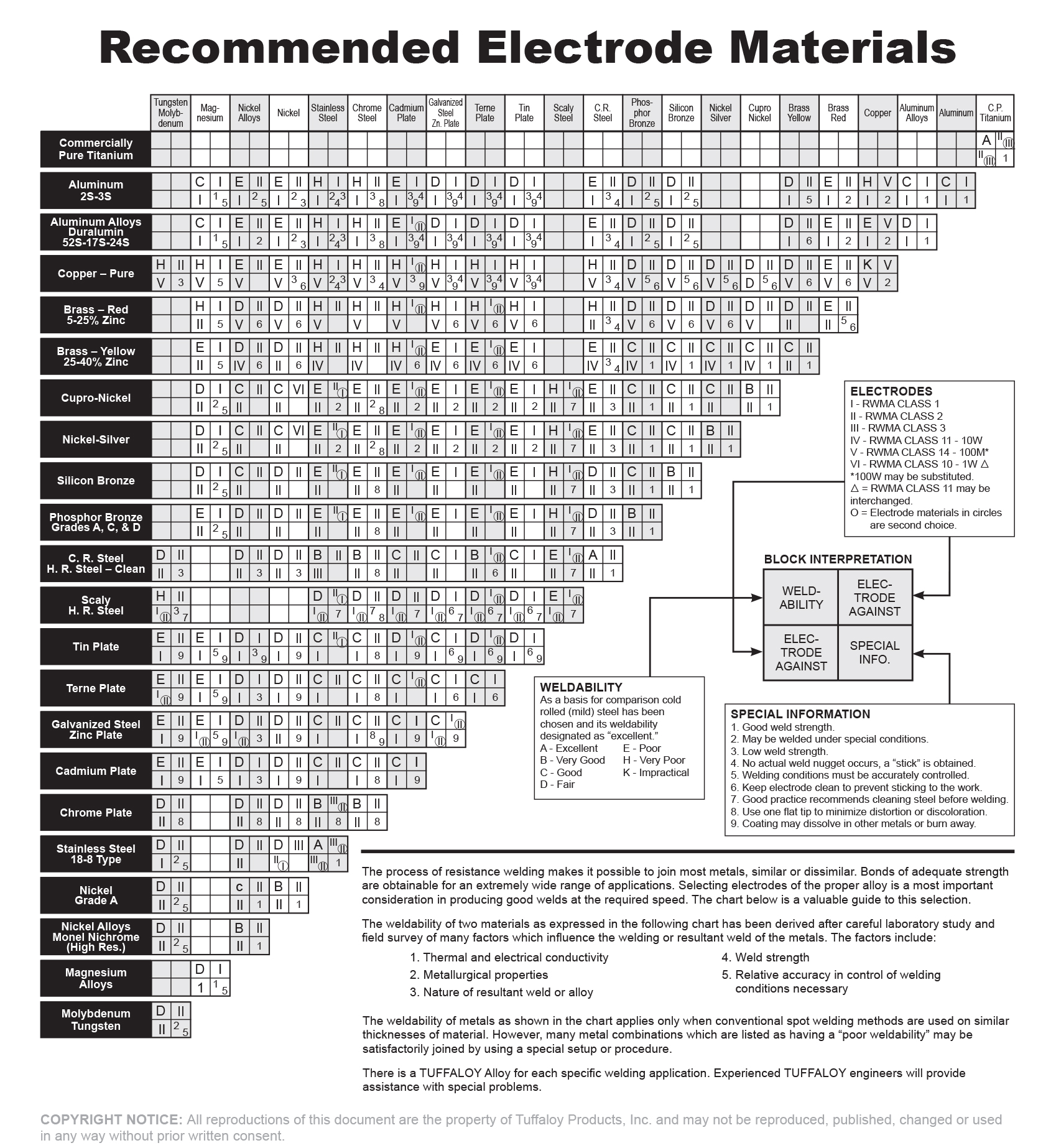

A simple short cut chart is available in the RWMA Manual Section 18-8 Table 18.3. If you know the two work piece materials being welded this chart will give you the proper electrode material to use for many similar and dissimilar materials.

Below is a very comprehensive chart from the CMW Inc. Resistance Welding Products Catalog whcih exhibits the electrode materials for spot welding.

References: CMW Inc. Resistance Welding Products Catalog

Tuffaloy Products Website & Catalog

AWS C1.1 Recomended Practices for Resistance Welding

RWMA - Resistance Welding Manual 4th Edition