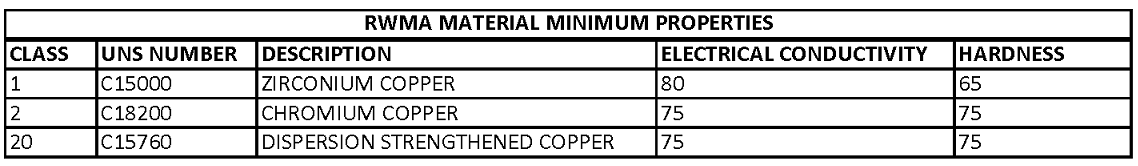

Class 2 material is a designation of the Resistance Welding Manufacturers Alliance (RWMA). This is a group of copper alloys with high strength and electrical conductivity. Class 2 is the most used material in the resistance welding industry. As electrodes it is used for welding bare and coated steels.

Class 2 Bar Stock

The product description and full properties of Class 2 can be found in the Resistance Welding Manual section 18-3, available at RWMA/AWS.

and

AWS Standard J1.3 Specification for Materials Used in Resistance Welding Electrodes and Tooling

Class 2 has very good strength and conductivity along with good heat resistance. Thes values have made it the most used material in the industry. It is fabricated into electrodes, holders, shanks, threaded adapters machine components and many other products in the resistance welding industry.

There are other copper alloy matertials not listed above Clasified by AWS J1.3. They can be seen in:

There are other Class materials with other properties shown in the above references. Their properties allow for welding work pieces with both higher and lower resistances and strengths than steel.

Reference: RWMA - Resistance Welding Manual 4th Edition

AWS J1.3 - Specification for Materials Used in Resistance Welding Electrodes and Tooling