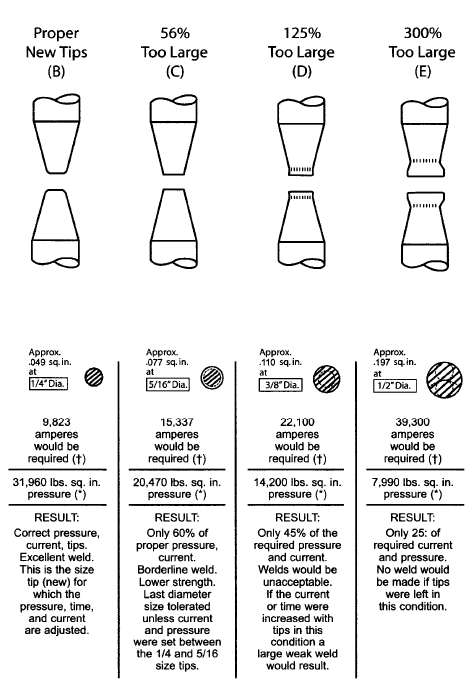

All electrodes wear and in the case of spot welding they mushroom. Therefor the face must be dressed back to original shape to maintain weld quality. If the weld face size is not controlled within some reasonable parameters there will be insufficient current to maintained the required weld nugget.

Every weld schedule is set up on a specific set of parameters to produce an acceptable weld nugget. As the electrode weld face grows the amount of current/current density is being spread out over a larger surface area. Therefor the heat is being reduced because we do not have enough current/current density to heat this growing surface area. The weld nugget size will reduce and eventually be discrepant.

During the set up process and initial runs we learn when and how to judge this point of electrode face growth and nugget failure. Based on this data we set up a maintenance schedule for the electrode and dress the face of the electrode back to original dimensions prior to reaching the point where the nugget quality is an issue. Yes, maintenance of the weld face to insure weld quality is necessary.

Reference: CMW Resistance Welding Products Catalog

RWMA Resistance Welding Manual 4th Edition