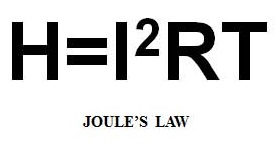

Aluminum is very conductive and therefore Has a very small resistance. To make up for this a very high current is required to generate heat per JOULES LAW.

If your equipment has the capability to deliver enough amperage and force then it can be used to weld aluminum.

Resistance welding requirements run:

• Amperages of 30,000 – 50,000 amperes would be common power requirements for aluminum using AC equipment.

• Additionally relatively high forces are required to contain the weld and forge the weld nugget. Forces of 5kn (1150 lb.) force up to 20 kn. (4500 lb.) can be expected.

• Weld times can run from 8 to 30 cycles.

This data is for:

Alloy 2024 Thickness from 0.64 mm (0.025 in) to 3.18 mm (0.1.2 in)

If your welder has the power and duty cycle capability to perform the above then you can weld aluminum. Your local machine distributors will be able to help you make this determination.

Different values are available for midfrequency powered systems. They will be similarly higher than the normal steel values.

Reference: AWS Standard C1.1 - Recommended Practices for Resistance Welding

RWMA – RWMA Resistance Welding Manual 4th Edition