In some materials there is a tendency for voids to form in the weld nugget. Aluminum often has this problem. Forging the nugget in the plastic state is a desirable means of improving the nugget’s strength and acceptance.

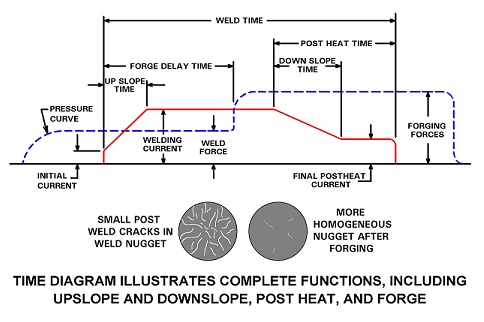

The timing diagram above shows the increasing force near the end of current weld sequence, while the metal is still in the plastic state. This forging force is applied to close the voids that would otherwise form as the aluminum solidifies. This operation is just like a blacksmith hitting the hot metal with his hammer as it cools to strengthen it.

Reference: RWMA - Resistance Welding Manual 4th Edition