If a shop is currently joining steel and stainless steel components, depending on the design and part specifications, spot welds can be successfully used. To do this the part design must be such to alloy room for the spot welds in sufficient quantity, size and location to meet the specified strength requirements. The materials being welded must also be of sufficient strength, thickness and stack up or combination of to have the proper resultant spot weld strength.

There are instances where there is insufficient space to design a flange for the desired number or size of spot welds. In these cases the spot weld might be used as a locator and a MIG weld might be used to add sufficient strength to the joint.

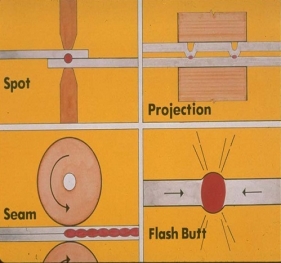

Sheet metal parts are being resistance welded in all industries. To name a few toys, store shelving, furniture, appliances, automobiles, aircraft and spacecraft are being resistance welded using one or more of the resistance processes of spot, projection, seam, butt and flash welding.