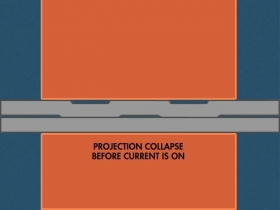

There are materials that due to their properties are not suitable for projection welding. This can be extended to thin cross section in other materials that could be projection welded in heavier gauges. The basic problem being that the material must be strong enough to withstand the force applied during the squeeze portion of the weld cycle. If the projections collapse before the weld/heating cycle begins, there is no longer a projection to concentrate the heat. It collapsed. The weld will fail. Materials that are generally not candidates for projection welding are brass, copper and red brass. Aluminum in some forms can be projection welded.

This increased surface area due to the collapsed projections will be very difficult to weld.

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Manual Section 1, Chapter 3