The answer is YES. AWS Standard J1.2M/J1.2:2016 Guide to the Installation and Maintenance of Resistance Welding Machines

This standard covers installation as well as ongoing maintenance. This applies to welding guns or machines.

Many spot welding guns and most resistance welding machines use air. All resistance welding operations use cooling water for the control, conductors, transformer and electrodes. Installation of the proper amount and quality of the air & water is important to the resistance welding operation.

AIR

The air system must be installed properly and maintained for proper resistance welding.

Air Quality:

1. Pressure 0-120 psi

2. Volume as specified by manufacturer

3. Pressure drop should not be greater than 10 psi

4. Filters – traps and filters to remove water and particulates must be present and checked.

5. Lubricators are frequently used, follow the manufacturer’s recommendations.

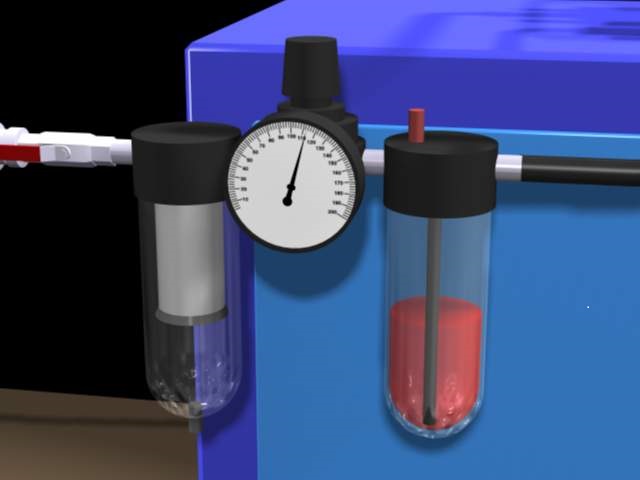

Pressure Regulator, Filter and Lubricator

WATER

Water pressure should be 75 psi maximum and a minimum of 30 psi pressure drop to insure flow.

Flow should be per the machine specifications.

Temperature should be 65-85 Degree F

Condensation on cooled components must be prevented.

Water Quality:

1. Maintain the pH between 7.0-9.0

2. Chloride maximum content of 20 ppm

3. Nitrate maximum content of 10 ppm

4. Sulfate maximum content of 100 ppm

5. Solids maximum content of 250 ppm

6. Calcium Carbonate maximum level of 250 ppm

7. Water resistivity greater than 2,000 ohm-cm

The water should be free of contamination such as algae growth and slime. Water which has an odor or is cloudy requires attention. Do not use water additives that will attack the circulation components including the rubber hoses. The water hoses should not contain graphite or carbon black which could make them conductive.

Deionized water should not be used. It can be corrosive to the water system and can lower the resistivity of the water.

Dirt and debris such as leaves blown into the water tower can lead to restricted water flow and overheating of the welder components. Strainers and filters should be check frequently.

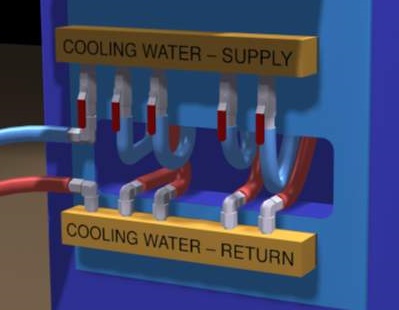

Water Manifold with Separate Lines for Components

The air and water - feed and exit lines should be at least as large as the machine connection points to insure adequate volume.

For additional information about installation and maintenance of resistance welding equipment consult:

AWS Standard J1.2M/J1.2:2016 Guide to Installation and Maintenance of Resistance Welding Machines

References:

AWS J1.2M/J1.2:2016 Guide to the Installation and Maintenance of Resistance Welding Machines

RWMA Bulletin 14

RWMA Bulletin 16

RWMA Resistance Welding Manual