Spot Welding

Questions and Answers

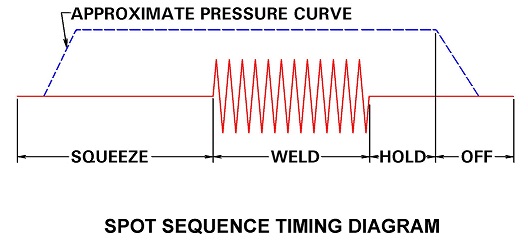

Everyone looks for a formula to set squeeze, weld, hold and off, but it basically does not exist. Equipment varies with different impedances, conductors, electrodes and tooling. Several articles have been written on this subject in the blog:

"HOW DO YOU SET THE PROPERS QUEEZE TIME IN A RESISTANCE WEDING SCHEDULE?"

"IS THERE A FORMULA TO DETERMINE THE SQUEEZE TIME IN RESISTANCE WELDING?"

"HOW WILL HOLD TIME CHANGE THE RESISTANCE WELD STRENGTH?"

Both titanium and carbon steel can be spot welded. Information on spot welding them to each other is something that is not readily available in the published literature. Using an intermediate filler metal makes joining them potentially easier. This is no longer a spot weld it has become a resistance braze. Depending upon the part size a resistance braze can be a few cycles or over a minute long. The goal is not to heat the whold part, just the braze medium.

Once again published literature does not have any information listed for the braze medium for resistance brazing titanium. Literature using other brazing methods does show that titanium is frequently brazed using Silver/Copper braze alloys. It is likely that one of these would be suitable for resistance brazing. Flux will be required and are generally available for most Silver braze alloys.

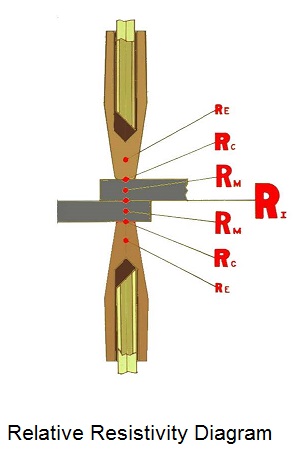

Force is one of the main inputs of the weld machine in the form of pressure exerted by the electrodes on the work piece. The main function of this force is to contain the weld by holding the work pieces together tightly during the welding operation.

Stronger work piece materials require higher welding forces than weaker work pieces. With adequate force the contact resistance between the electrode and part is minimized and more energy is transmitted into the part to heat the interface between the two sheets being welded.

There are many variables in nut welding that can change. In your inquiry it was stated that the material and weld nuts were the same. Are they?

Is this coated material? Is the coating the same everywhere all of the time? Is the material clean or oxidized consistently?

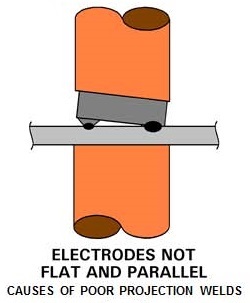

Projection weld nuts are known to have variable projections in size, shape and height.

Does the nut feed onto the locating pin properly or hang up once in a while?

Is the locating pin properly insulated? Has the insulation worn? Is current shunting through the pin?

Is the weld cylinder hesitating/hanging up and not moving fast enough? Fast follow up for cylinders or servos is imperative for weld strength.

Is the tooling aligned properly for even touch down of all equal projections?

Projections missing or wrong size will cause the same problem as above.

Have any shunts or cables begun to wear or insulation worn? Worn cables and shunts will definitely change the weld results.

This is a very common material in the industry and there are many publications with weld schedules available. These schedules were developed on specific machines and material with specific chemistry and properties. Your machine and material will vary. These schedule settings will produce a weld but may require some adjustment to produce the best results for your particular situation, material and equipment.

Page 17 of 44

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.