This is a very common material in the industry and there are many publications with weld schedules available. These schedules were developed on specific machines and material with specific chemistry and properties. Your machine and material will vary. These schedule settings will produce a weld but may require some adjustment to produce the best results for your particular situation, material and equipment.

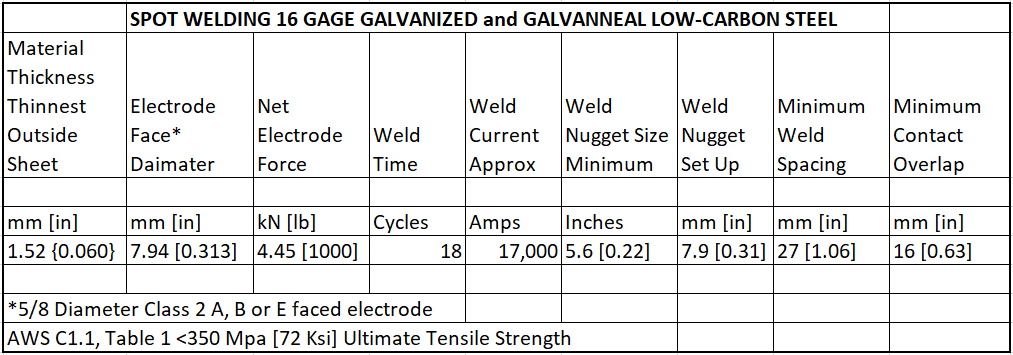

Below is data drawn from AWS Standard C1.1:

For expanded sizes and steel alloys see the additional chart data in AWS C1.1 available through the American Welding Society.

For a complete discussion of welding 16 gauge sheet metal see a previous article in this blog:

“WHAT IS THE BEST METHOD TO SPOT WELD 16 GAGE ELECTROGALVANIZED SHEET METAL?”

Specifics parameters for individual machines or controls are beyond the scope of this website. Schedules are always a guide to get one close to what will be the end result. With some modest adjustment these schedules will produce good product.

Additional sites for weld schedules of various materials and sizes can be found in the references listed below.

References: AWS: AWS Standard C1.1

RWMA: Resistance Welding Manual 4th Edition

CMW Inc.: Welding Products Catalog

Tuffaloy Products: Resistance Welding Products Catalog