Seam welding can generate large amounts of heat. Especially when making a liquid tight continuous weld. This heat is very visible at the actual weld joint. Heat is also being created in the various conductors, transformer and the control. All of these components must be cooled. The control, transformer and conductors should all be cooled per the amount specified by the supplier of that equipment. The seam weld wheels are mounted on water cooled shafts which also are water cooled. All of these components will generally be cooled with 1-1.5 gallons of water per minute of flow per device. The flow to the various components should come from the water manifold separately to insure cool water for each component.

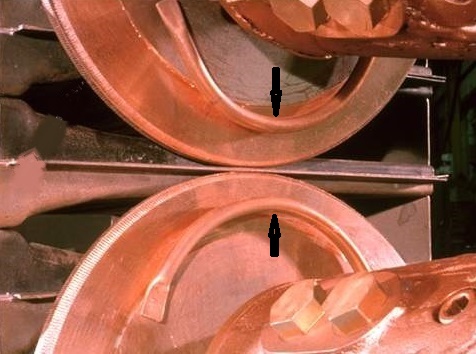

Seam Welder with External Flood Cooling Tubes Near Weld Area

The part and wheel will frequently be cooled externally by flood cooling directly on the part/wheel weld area. The general rule of thumb is a flow rate of 1-1.5 gallons per minute.

The cooling water temperature should be near room temperature for optimum performance. Most facilities use recirculating water towers. Water chiller systems are available if more cooling is required.

Reference: RWMA – Resistance Welding Manual Section 4