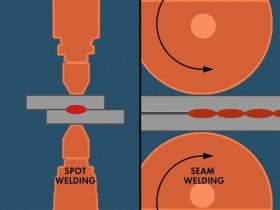

Seam welding is very similar to spot welding. There is still an electrode but it is two opposing wheels rather than two pointed electrodes. Force and current is applied through the wheel just as in spot welding. The control timing and wheel speed determine the spacing of the spots. They can be made to overlap and be fluid tight or separated. If separated this is called a roll spot weld. Fluid tight applications could be dishwashers, washing machines, tin cans and metal drums.

Reference: AWS C1.1 Recommended Practices for Resistance Welding

RWMA Manual Section 4