It certainly is possible but may not be practical to convert a spot welder into a seam welder. Many major components will need to be examined and potentially redesigned or changed. This would include the transformer, conductors, machine weld head, control and plant input power to name a few. This conversion will involve the potential change from a standard electrode to a seam welding wheel and a rotating weld held mechanism. This is a major machine design change. This should be addressed with a machine builder or rebuilder of used machinery. This question is beyond the scope of this discussion.

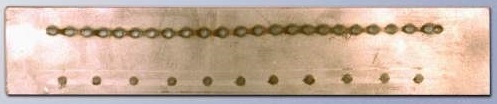

If one wants to use a spot welder to make spot welds close together. These are referred to as stitch welds.

VARY SPOT SPACING TO MAKE

A STITCH WELD

This is a common process and is practiced regularly with standard equipment.

Please refer to another article in this blog:

"HOW LONG IS REQUIRED TO STITCH LAP WELD?"

A stitch weld can be very effective and efficient.

Reference: RWMA Manual 4th Edition