A stitch weld is a series of spot welds made in a row down two pieces of material. It is similar to a seam weld but is a weld gun or machine cylinder applying the individual welds rather than a rolling seam welding wheel.

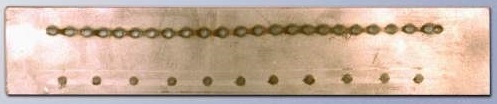

VARY SPOT SPACING TO MAKE A STITCH WELD

These welds can be a lap joint or to join metal together as shown above. How long will the weld take? This is determined by the weld schedule necessary for one weld. From this one schedule one would multiple by the number of welds necessary and add the move time between welds.

Using the figure above count the number of desired welds, times the weld time, and add in the time to move/fixture to the next position.

The upper figure has many more welds. It will obviously take longer than the figure on the lower part since there are fewer welds. Indexing the position in either circumstance can be automated and done quickly. That is the time to weld the above part.

I have seen a furnace blower cage end piece welded without weld placement precision in 1-3 seconds. The operator fired the welder like a machine gun for a second or so and flipped to the other end did it again for another 1-3 seconds and was done. The end piece was secured in place with individual welds 1-4 inches around the periphery.

A stitch weld can be very effective and efficient.

Reference: RWMA Manual 4th Edition