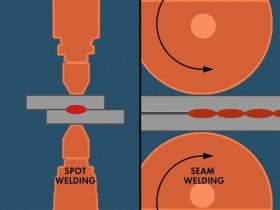

Seam and spot weld are similar in many ways. They both make individual welds with the same basic process of squeeze, weld and hold. The heating principal is the same “Ohm’s Law” H = I2 rt. The electrodes are different. One employs a wheel the other a single point electrode. Their weld faces are a little different but still act to concentrate the current and force into a point contact on the part. In simple terms they produce the same individual welds.

Seam welds generally are closer together and frequently produce fluid tight seals. Spot welds normally are not that close together and are not water tight. Testing is performed on seam and spot welds in similar fashion by destructive testing of coupons or product in most shops.

Seam welding wheels are driven and move the work piece. Spot welds electrodes are stationary and the product comes to it or robots move the weld electrodes to the weld locations.

Reference: RWMA – Resistance Welding Manual Section 4