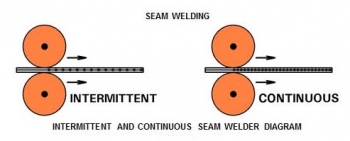

Intermittent and continuous seam welds are very similar. In fact they can be run on the same machine. The only difference is the spacing of the weld. A change in the machine settings could produce either weld.

A continuous seam weld is one where the individual spot welds produced overlap and normally form a fluid tight seam weld. Intermittent welds are spaced out and therefor are not fluid tight. Sometimes this type of weld is referred to as a roll spot weld. Generally the roll spot/intermittent process can produce more feet of product faster than the continuous seam weld.

Reference: RWMA – Resistance Welding Manual Section 4