Metal pickup on the wheels can definitely change the welding parameters at the welding interface. The geometry of the weld face has changed and the contact resistance has changed. Both will have a large affect upon the heat at the weld interface. Many machines have knurled welding wheels. The knurl can maintain a constant fresh geometry and face condition by continually recutting the seam weld wheel as it rotates.

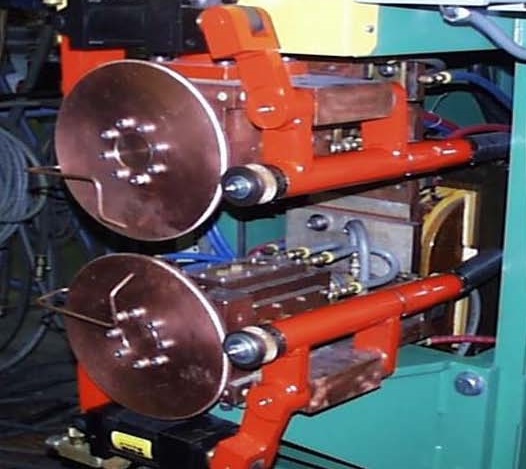

KNURL DRIVEN WHEELS

An additional issue to consider is proper force maintenance. AWS Standard C1.1 Table 3 calls for 900 lbs force on the part for 0.79 mm (0.031 in) material. This is not the air pressure supply but force on the part. This can be calculated based on the supply psi gauge and calculate using the size of the machine cylinder. The other option is to use a force gauge to measure the force between the wheels.

FORCE GAUGE

Another factor which cannot be overlooked is that heat could build up after welding several parts. Check the machine cooling system to insure it is functioning properly. If cooling at the wheel face and part interface is a problem that other remedies cannot solve, Flood cooling is always an option.

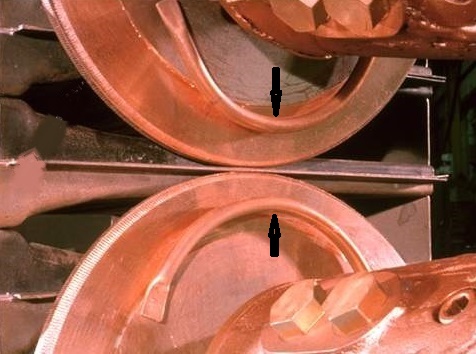

ARROW INDICATES FLOOD WATER TUBES

Reference: RWMA – Resistance Welding Manual Section 4

AWS C1.1 Recommended Practices for Resistance Welding