Seam Welding

Questions and Answers

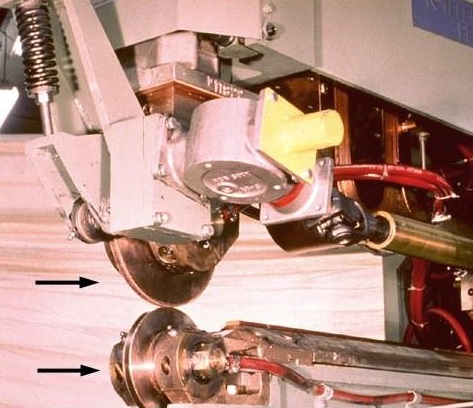

All seam welders are designed and built with precision bearings, a moving shaft that extends to the seam welding wheel, and conductive shoes that rotate on the shaft to pick up the current from the stationary conductors in the housing. The entire housing is sealed and contains a conductive grease or lubricant to insure long life and good electrical conduction.

This housing and shaft assembly is a very precise piece of machinery designed to last for many years with proper maintenance. Maintenance of lubrication would be one of those items.

An article on Seam Shaft maintenance is available:

CAN WORN SEAM WELDING SHAFTS BE REWORKED?

KNURL DRIVEN SEAM WELDER

Should one permit a seam welder head to run low on lubricant is an obvious answer, NO.

It would be similar to running your vehicle engine or transmission low on oil or transmission fluid. Eventually the engine freezes up or the transmission fails to shift.

No one wants to reach that point. Follow the manufacturers maintenance instructions.

The other alternative is to establish an in-house preventive maintenance procedure.

American Welding society has a standard available to serve as a guide for and in house preventative maintenance program.

AWS Standard J1.2- “Guide to Installation and Maintenance of Resistance Welding Machines”

References: RWMA Resistance Welding Manual 4th Edition

AWS J1.2 Guide to Installation and Maintenance of Resistance Welding Machines

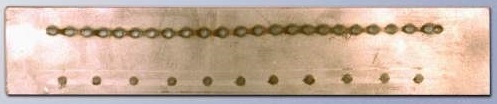

The seam weld wheels perform two functions. One is to function as an electrode and deliver the force and current into the part at the desired weld interface. This is a moving location as the wheels roll.

ROLL SPOT SEAM WELDS

The second function is to move the part into position for each new weld. One or both wheels may be driven to perform this function. In some cases, the part is driven and the wheels float and follow the part movement.

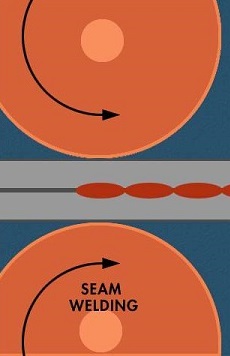

In all circumstances the direction of the wheel motion at the part surface is always the same direction as the part motion.

If the part is moving into the throat of the machine. The upper and lower wheels will both turn with a motion into the throat of the machine. At the surface they are both moving in the same direction. If one wants to talk clockwise vs counterclockwise, if the upper is turning clockwise the lower is counterclockwise. If you look from the other side of the machine the opposite is true.

SEAM WELD WHEEL ROTATION

Always both wheel surface motions are in the direction of the material motion.

Reference: RWMA – Resistance Welding Manual 4th Edition

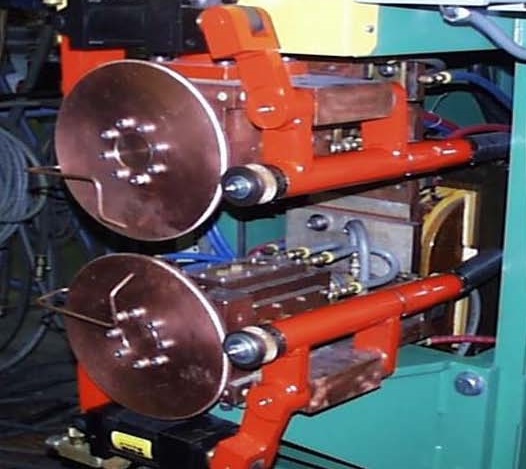

On some products it is desired to use two different sized weld wheels. They likely will be the same thickness and face contour. Due to the diameter difference the larger diameter wheel will have more material in contact

with the part surface than the smaller wheel. This reduces the current density on the large wheel surface and the heat generated there in comparison with the small wheel’s surface.

SEAM WELDER WITH TWO DIFFERENT WHEELS

The amount of this differential will depend upon the material being welded, wheel sizes and weld schedules used.

Additional discussion of this subject can be found in another article in this blog:

WHEN SEAM WELDING WITH ONE LARGE AND ONE SMALL DIAMETER WHEEL CAN THE WELD NUGGET FORM TOWARD ONE SIDE OR THE OTHER?

Reference: RWMA – Resistance Welding Manual Section 4

The lubricant used in seam welding heads is very important. It must lubricate the moving gears and parts and the conductive power components. It should be conductive and withstand heat.

KNURL DRIVEN SEAM WELDER

The specification of the lubricant depends upon the design of the product and the manufacturer. This is machine specific. This question is beyond the scope of this blog. The manufacturer of the equipment or a rebuilder should be consulted for help on this topic.

Reference: RWMA Manual Section 4

In the normal standards which I reference there is very little data for material this thin. AWS Standard C1.1 has set up data for Stainless Steel at 0.38 mm (0.015 in) thick but no testing information of the welds.

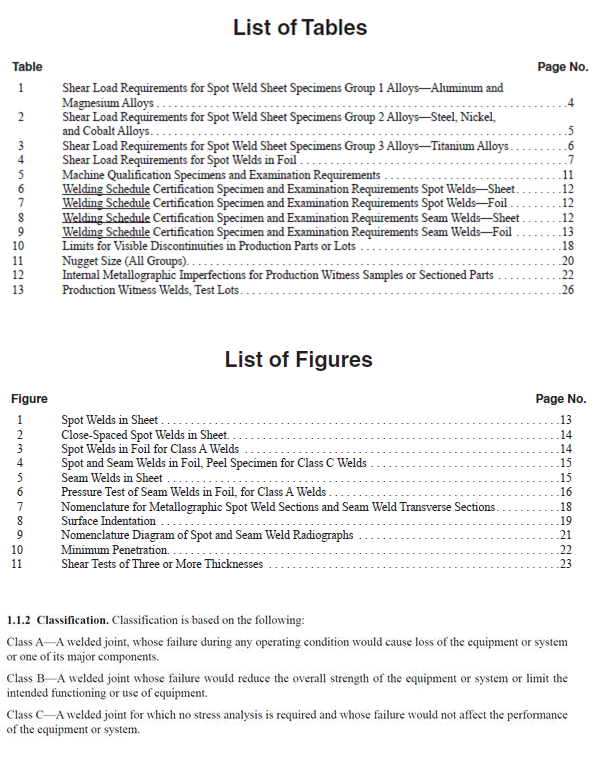

Further discussion with colleagues revealed that anything below 0.2 mm (0.008 in) is considered foil per AWS Standard D17.2 (An Aircraft Specification). Below is the table of contents for this standard AWS D17.2. It may offer some insight to this inquiry?

AWS D17.2

If the end user has not supplied a specification, then consider calling the weld either Class B or Class C and evaluate accordingly.

Reference: AWS C1.1, Recommended Practices for Resistance Welding

AWS D17.2, Specification for Resistance Welding for Aerospace Applications

Page 2 of 15

Have a Question?

Do you have a question that is not covered in our knowledgebase? Do you have questions regarding the above article? Click here to ask the professor.