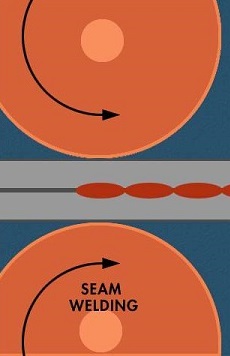

The seam weld wheels perform two functions. One is to function as an electrode and deliver the force and current into the part at the desired weld interface. This is a moving location as the wheels roll.

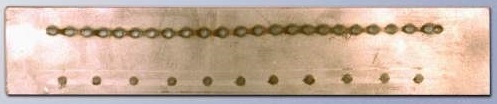

ROLL SPOT SEAM WELDS

The second function is to move the part into position for each new weld. One or both wheels may be driven to perform this function. In some cases, the part is driven and the wheels float and follow the part movement.

In all circumstances the direction of the wheel motion at the part surface is always the same direction as the part motion.

If the part is moving into the throat of the machine. The upper and lower wheels will both turn with a motion into the throat of the machine. At the surface they are both moving in the same direction. If one wants to talk clockwise vs counterclockwise, if the upper is turning clockwise the lower is counterclockwise. If you look from the other side of the machine the opposite is true.

SEAM WELD WHEEL ROTATION

Always both wheel surface motions are in the direction of the material motion.

Reference: RWMA – Resistance Welding Manual 4th Edition